TECHNOLOGY

2023.08.25

Metal Surface Treatment Topic: Environmental Benefits and Advantages of Electroless Nickel

GearKo’s planetary gear reducers feature exterior metal components are treated with human-friendly electroless nickel (chemical nickel) plating, in compliance with international environmental and safety standards.

MORE

2023.08.18

Gear Hobbing and Power Skiving: The New Trend in Internal Gear Machining

Hobbing is a common method for internal gear machining. Power Skiving is a new, efficient technique, reducing processing time by 3 to 8 times. GearKo produces high-precision reducers using this method.

MORE

2023.08.15

Planetary Reducer Selection Guide: Practical Calculation Example

Through actual examples, we guide you step by step to understand the selection process of gearboxes.

MORE

2023.08.11

Planetary Reducer Selection Guide: Complete Analysis of 14 steps

This article provides a detailed introduction to the selection process of planetary gear reducers, including the calculation of operating modes, reduction ratios, output torque, etc.

MORE

2023.08.01

Mastering the Power of Planetary Gear Reducers: Ten Features of Planetary Gear Reducers You Need to Know

This article provides a detailed introduction to the functions and working principles of gear reducers, including how to change rotational speed and torque by adjusting the number of gear teeth. Additionally, practical suggestions for selecting the appropriate gear reducer are provided.

MORE

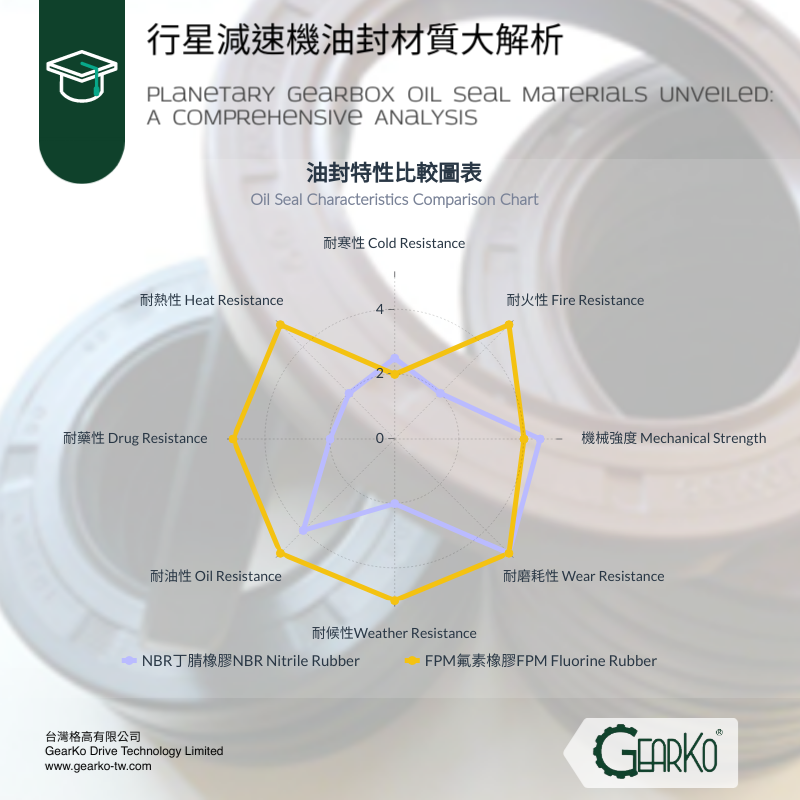

2023.07.28

A Comprehensive Analysis of Planetary Gear Reducer Seal Materials

GearKo planetary gear reducers use a TC rotary seal design, offering both NBR and FKM materials for the seals. Both materials meet IP65 protection standards.

MORE