2023.07.28

A Comprehensive Analysis of Planetary Gear Reducer Seal Materials

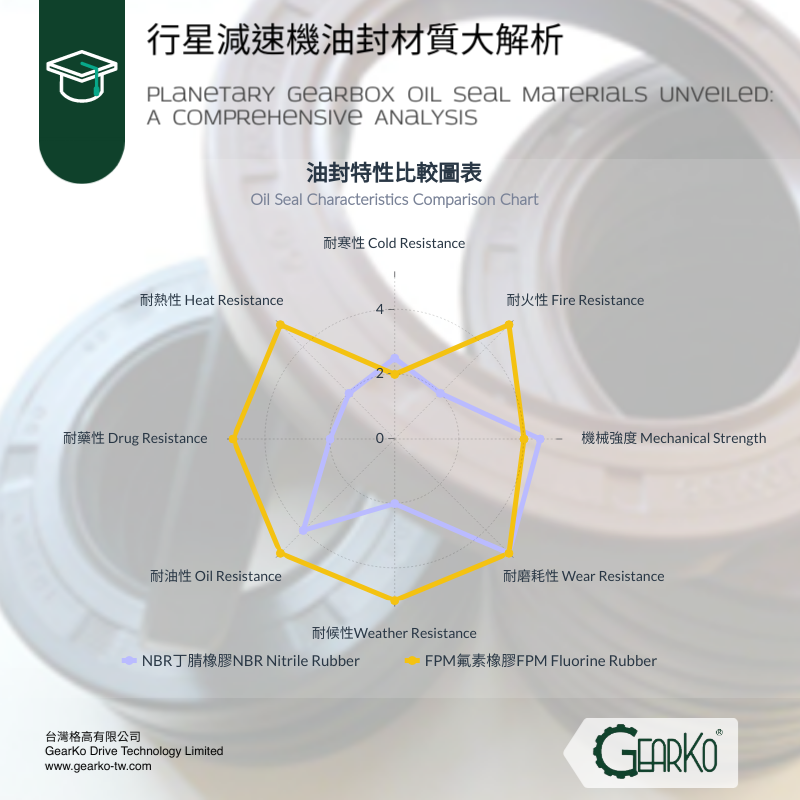

GearKo planetary gear reducers adopt a TC rotary seal design, offering both NBR and FKM materials for the seals, the characteristics of which can be compared in the figure at the beginning of this article. Both materials achieve an IP65 protection level. The standard version uses NBR material, while FKM material can be chosen for special high-standard environments. The differences between the two are explained below:

Nitrile Rubber (NBR): The most commonly used oil-resistant rubber, with excellent abrasion and oil resistance, is inexpensive, but has poor weather resistance. It should be kept away from direct sunlight and ozone-rich environments as much as possible. The chemical and physical properties of nitrile rubber vary with the cyanide content in the polymer, the higher the cyanide content, the stronger the corrosion resistance, but the elasticity and insulating properties are worse, making it unsuitable as an insulating material. The general use temperature is around -25°C to 100°C, and the life of nitrile rubber will be shortened when exceeding 100°C.

Fluorocarbon Rubber (FKM/FPM): A high-performance rubber formed by polymerization of fluorinated hydrocarbons, with high tensile and structural strength. Fluorocarbon rubber has excellent high-temperature resistance, wear resistance, weather resistance, oil resistance, and drug resistance, with nearly all characteristics being excellent. It has good electrical insulation, but is more expensive and unstable to polar solvents. The general use temperature is around -20°C to 250°C.

Please refer to the table below for a comparison of drug resistance of the two materials:

|

|

NBR Nitrile Rubber |

FPM Fluorine Rubber |

|

Gasoline (Petrol) Light Oil |

Excellent |

Excellent |

|

Water |

Excellent |

Excellent |

|

Strong acid |

Good |

Excellent |

|

Strong alkali |

Good |

Incompatible |

|

Ether |

Incompatible - OK |

Incompatible - OK |

|

Ketone |

Incompatible |

Incompatible |

In conclusion, if your application requirements are within the standard range, the regular NBR seal should sufficiently meet your needs, while also being cost-effective. NBR seals perform well in terms of oil and abrasion resistance and are suitable for the general temperature range.

If you have any questions about GearKo's planetary gear reducers' products or services, or if you need more detailed information, please feel free to contact us. Our team will provide you with dedicated support and assistance. We look forward to working with you!