2023.08.01

Mastering the Power of Planetary Gear Reducers: Ten Features of Planetary Gear Reducers You Need to Know

Gear reducers are not only a core part of mechanical engineering but also play an important role in many industrial applications. This article will guide you in understanding the functions and features of gear reducers and offer practical advice for choosing the appropriate reducer.

What is a Gear Reducer?

Simply put, a gear reducer is a transmission mechanism that can lower the rotational speed inputted by a motor while increasing the output torque. By using a motor, internal combustion engine, or human power at the input end of the reducer, a small force can generate a larger force at the output end through the transmission of gears. This force is referred to as torque and can drive a larger load. Torque units: SI international unit is Newton-meter N·m, metric kgf·m, imperial lbf·ft.

Working Principle of Gear Reducers:

Generally, to create a reduction effect, the prerequisite is that the input gear's number of teeth must be smaller than the output gear's. The ratio of the number of teeth between the large and small gears is known as the reduction ratio (i) or transmission ratio (i = large gear : small gear).

The relationship between the reduction ratio and torque is a mutual constraint, as sometimes there is a speed requirement that cannot be met if the reduction ratio is too large. In a mechanical transmission system, as the reduction ratio increases, the angular velocity of the output shaft decreases, slowing the output speed. However, the torque on the output shaft will increase as the reducer amplifies the energy provided by the input shaft through mechanisms like large and small gears, thereby generating more significant torque. Simply put, the greater the reduction ratio, the higher the output torque, and the slower the output speed.

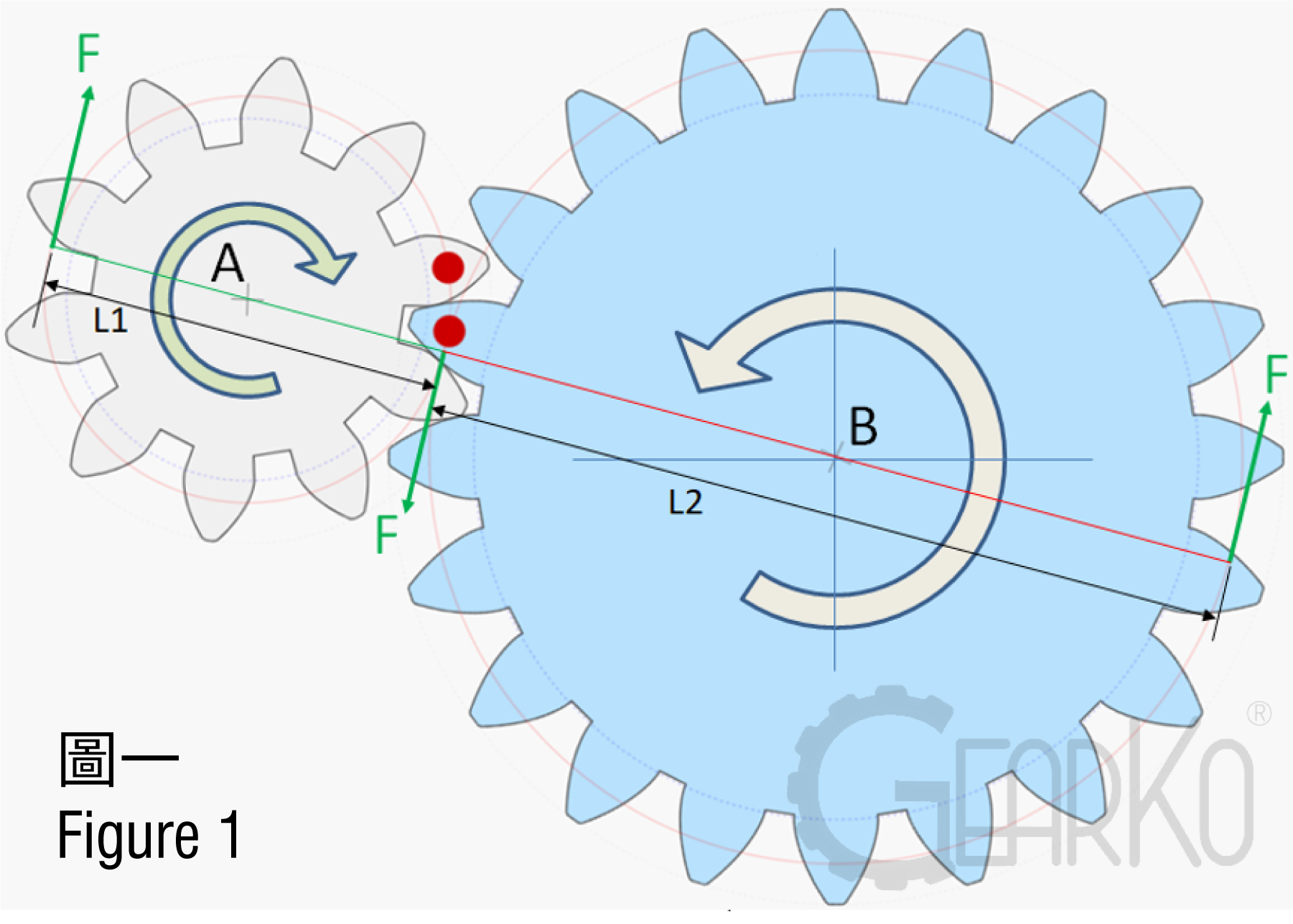

The illustration below (Figure 1) explains how torque can increase. If gear A has 10 teeth and gear B has 20 teeth:

(1) A is the input gear (driving gear), with a torque of Ta = FxL1.

(2) B is the output gear (driven gear), where FxL2 = Tb.

Since gear A has 10 teeth and gear B has 20 teeth, i = 20:10 = 2:1, so L2 = 2xL1, substituting into equation (2)

Tb = Fx2xL1 = 2FxL1 = 2Ta.

From the above calculation, we find that Tb = 2Ta. Thus, assuming the input torque Ta = 5Nm, the output torque Tb = 10Nm, neglecting energy loss.

Types of Gear Reducers:

Gear reducers can be divided into several types based on transmission and structural characteristics: Gear reducers, Worm wheel reducers, Planetary gears, Cycloid reducers, and Harmonic drive reducers, etc. Each of these reducers has its unique features.

Advantages of Planetary Gear Reducers:

1. Increased Torque: Often used in industrial automation applications for low-speed, high-torque precision control.

2. Improved Accuracy: High meshing precision between gears, less than 1 arc minute. It is considered a high-precision gear reducer.

3. High Efficiency: Transmission efficiency can generally reach 97%.

4. Motor Protection: Reduces potential motor damage during overloads.

5. Energy Saving: Achieves desired torque at a lower cost by using a smaller servo with a reducer, and saves energy.

6. Easy Maintenance: In case of overload failure, replacing the reducer is convenient and quick.

However, there are also disadvantages:

The following are four common drawbacks of planetary gear reducers:

1. High Cost: More expensive compared to regular gear reducers.

2. High Precision Manufacturing Requirement: Precise machining is needed to prevent early wear and failure.

3. More Complex Structure: Maintenance requires higher professional skills and repair costs.

4. Decreased Accuracy with Double Stages: Accuracy may decrease when reduction ratio exceeds the maximum ratio for a single stage, usually 10:1 for planetary gear reducers.

The above ten features of planetary gear reducers are provided for reference.

Choosing the right planetary gear reducer can maximize your equipment's efficiency. GearKo gear reducers in Taiwan boast excellent precision, rigidity, and reliability, with a CP value that matches any quality brand. For questions about pairing motors and planetary gear reducers, feel free to call or email GearKo in Taiwan.