2023.08.18

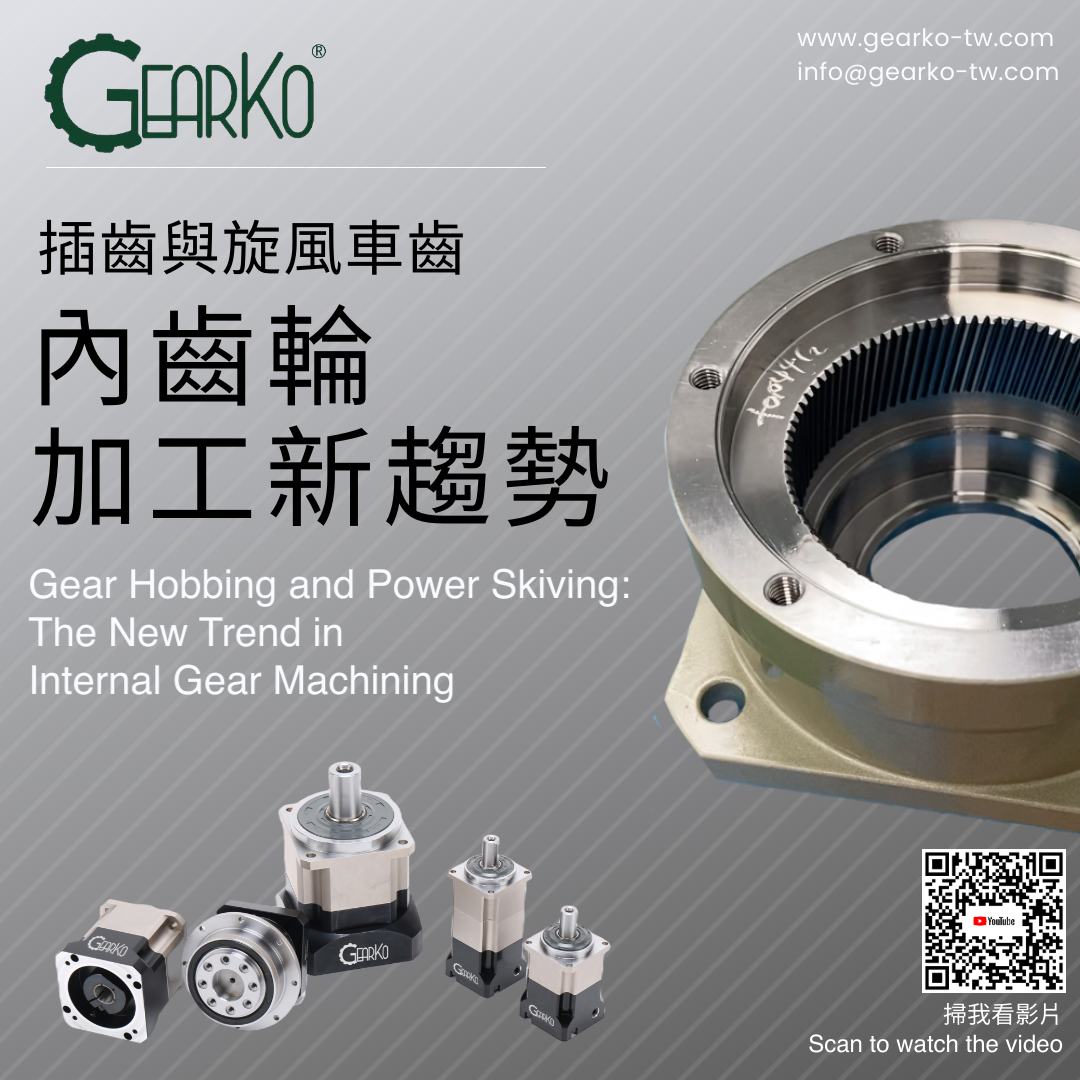

Gear Hobbing and Power Skiving: The New Trend in Internal Gear Machining

Gear hobbing is currently a widely used method for internal gear machining, which can be understood as the meshing movement of a pair of cylindrical gears. The making of a gear hobbing cutter is akin to creating a worm wheel. During the gear hobbing process, the hob moves up and down. After the tool cuts downward to the bottom, it retracts radially to prevent the tool from scratching the already machined surface. Then, the hob quickly moves back up to the highest point, repeating the cycle. This machining action is completed through the cyclical movement of gear generating motion and radial feed motion of the workpiece.

Power Skiving is a new and efficient method of gear machining. It is typically performed through the synchronized movement between the workpiece axis and the tool axis, and a special intersecting angle between these two axes (the axis crossing angle). Both axes rotate at high speeds synchronously. The tool axis cuts along the direction of the workpiece axis to carve out the desired teeth, shortening the machining time by 3 to 8 times compared to traditional hobbing.

The internal gear rings produced by GearKo planetary reducers are all machined using the Power Skiving technique. Paired with high-precision clamping fixtures, they have high stability and concentricity. The gear profile, helix angle, straightness, pitch error, total pitch error, and runout error all comply with German standards of DIN 6 or higher, making GearKo planetary reducers more economical and durable.

Please refer to the table below for a comparison of the two machining methods:

|

|

Gear Hobbing |

Power Skiving |

|

Equipment Cost |

Low |

High |

|

Compatibility with Other Processes |

Not Compatible |

Compatible with Turning, Milling, and Drilling |

|

Machining Time |

Slow |

Fast |

|

Cutting Tools |

Powder High-Speed Steel |

Tungsten Steel |

|

Tooling Cost |

Low |

High |

|

Workpiece Hardness Capability |

Below HRC 30 |

Above HRC 30 |

|

Highest Machining Precision |

Low |

High |

|

Fixture Cost |

High |

High |

We look forward to your contacting GearKo. GearKo boasts a professional research and development, and manufacturing team in Taiwan. For many years, we have focused on the field of planetary reducers. We can provide the best solutions based on your needs.