2023.08.15

Planetary Reducer Selection Guide: Practical Calculation Example

In the previous article, we have detailed the 14 steps of selecting a planetary gearbox. Next, we will guide you step by step through the selection process of gearboxes using actual examples!

Example chosen:

Using a 400W motor (60 frame), rated torque 1.3Nm, maximum torque 4.5Nm, rated speed 3000r/min, maximum speed 6000r/min.

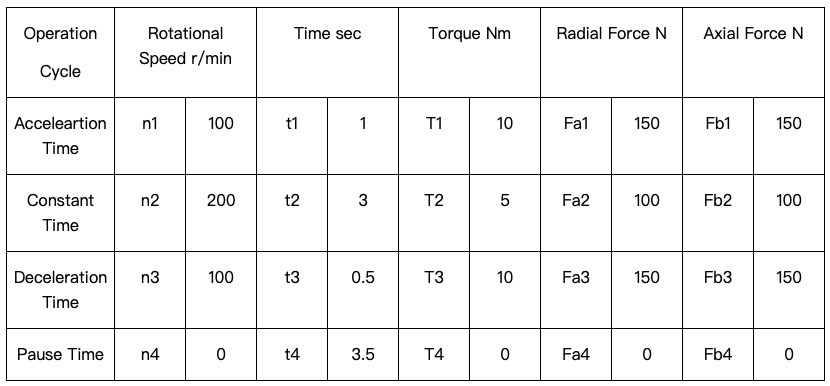

The operating data is as shown in Table 1 below:

(Table 2)

Evaluation Selection Criteria:

- Operating Mode: ED=(t1+t2+t3)/tx100%

(1+3+0.5)/(1+3+0.5+3.5)x100%=56.25%

56.25%(ED)<60%,Total cycle time of 8 seconds (t) < 20 minutes. (Falls under cyclical operating mode.) - Reduction Ratio:i = Motor Output Speed / Reducer Output Speed (Actual Maximum Speed)

3000/200=15 - Average Output Torque (T2m): (T2m)=³√[(n1xt1xT13+n2xt2xT23+n3xt3xT33)/(n1xt1+n2xt2+n3xt3)]

³√[(100x1x103+200x3x53+100x0.5x103)/(100x1+200x3+100x0.5)]=6.69(Nm) - Maximum Output Torque (T2max): T2max=Motor Maximum Output Torque × Reduction Ratio × Transmission Efficiency × Load Coefficient

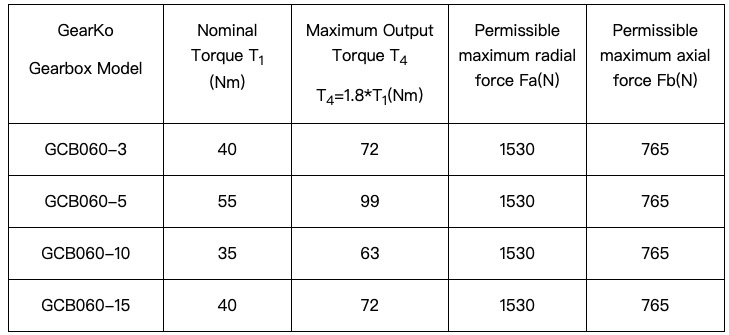

4.5x15x0.97x1=65.48(Nm) - Inquire about the Reducer's Rated Torque (T1) and the Reducer's Maximum Output Torque (T4):

Refer to Table 2: (GCB060-15),(T1)=40,(T4)=72

- Compare T2m with the Reducer's Rated Torque (T1) and T2max with the Reducer's Maximum Acceleration Torque (T4)。

6.69(T2m)<40(T1),65.48(T2max)<72(T4)。(Correct Choice) - Average Output Speed (S3)=(n1xt1+n2xt2+n3xt3)/(t1+t2+t3)

(100x1+200x3+100x0.5)/(1+3+0.5)=166.67(r/min) - Rated Output Speed (S4) =Reducer rated input speed/reduction ratio

3000/15=200(r/min) - Compare S3 and S4。

166.67(S3) <200(S4)。(Correct Choice) - Average Radial Force (Fc) and Axial Force (Fd) at the Output End

Average Radial Force (Fc) (Fc)=³√[(n1xt1xFa13+n2xt2xFa23+n3xt3xFa33)/( n1xt1+n2xt2+n3xt3)]

³√[(100x1x1503+200x3x1003+100x0.5x1503)/( 100x1+200x3+100x0.5)]=113.83(N)

Average Axial Force (Fd) (Fd)=³√[(n1xt1xFb13+n2xt2xFb23+n3xt3xFb33)/( n1xt1+n2xt2+n3xt3)]

³√[(100x1x1503+200x3x1003+100x0.5x1503)/( 100x1+200x3+100x0.5)]=113.83(N) - Inquire about the Allowable Maximum Radial Force (Fa) and Axial Force (Fb) at the Output End:

Refer to Table 2 (GCB060-15),(Fa)=1530,(Fb)=765

- Compare the values of Fc with Fa and Fd with Fb

113.83(Fc)<1530(Fa),113.83(Fd)<765(Fb)。(Correct choice) - Verify Precision Requirements: Assess the actual precision requirements for usage. Typically, precision is directly proportional to the price.

- Confirm the Dimensions of the Output and Input Connection Interfaces: Connection dimensions are crucial as they determine whether the reducer can be correctly assembled and integrated with the equipment and motor.

Based on the evaluation steps mentioned above, the results are as follows:

a. Operating Mode: Cyclical Operating Mode

b. Reduction Ratio i: 1:15

c. Average Output Torque (T2m): 6.69 Nm

d. Average Output Speed (S3): 166.67 r/min

e. Average Radial Force (Fc): 113.83 N

f. Average Axial Force (Fd): 113.83 N

Evaluation Result: The GearKo reducer specification GCB060-15 can be used.

Further Evaluation:

After evaluating the above example, the specification obtained is GCB060-15. This reducer is a two-stage reducer, and the price of a two-stage reducer is definitively higher than that of a single-stage. Therefore, next, we will use reduction ratios of 3, 5, and 10 to evaluate if they can also be utilized.

From the steps mentioned above, it's observed that if the ratio changes, only steps 4, 5, 6, 8, and 9 need to be reconfirmed. Following a recalculation, inquiry, and comparison according to each of these steps, the results are presented below.

|

Step |

Content |

GCB060-3 |

GCB060-5 |

GCB060-10 |

|

Step4. |

Maximum Output Torque (T2max) |

13.1 |

21.83 |

43.65 |

|

Step5. |

Inquire about the Reducer's Torque (T1)、(T4) |

(T1)=40,(T4)=72 |

(T1)=55,(T4)=99 |

(T1)=35,(T4)=63 |

|

Step6. |

Compare T2m and T1 &T2max and T4 |

6.69(T2m)<40(T1) 13.1(T2max)<72(T4) OK |

6.69(T2m)<55(T1) 21.83(T2max)<99(T4) OK |

6.69(T2m)<35(T1) 43.65(T2max)<63(T4) OK |

|

Step8. |

Rated Output Speed (S4) |

1000 |

600 |

300 |

|

Step9. |

Comapre S3、S4 |

166.67(S3) <1000(S4) OK |

166.67(S3) <600(S4) OK |

166.67(S3) <300(S4) OK |

From the comparison table above, we can see that single-stage reducers with ratios of 3, 5, and 10 are all suitable for use. However, typically in reducer design, a 5:1 ratio will have a larger rated torque, and its gears are also more robust.

Based on the evaluations of the various criteria mentioned above, it's recommended to use the GearKo reducer with the specification GCB060-5. Moreover, the price of a single-stage reducer remains the same regardless of its reduction ratio, so it's always better to opt for a more robust model.

Additionally, if there are space constraints or any other specific requirements, it's essential to inform the design personnel in advance. Only then can the design team evaluate and recommend specifications that meet the exact needs of the application.

Conclusion:

Through comprehensive evaluations and considerations, you can determine the reducer specification that best fits your needs. If you have any questions regarding the selection of planetary gear reducers, please feel free to call or email GearKo in Taiwan for assistance.