2024.02.02

Gear Wear Depth Study: GearKo’s Comparative Analysis of Performance Between Spur and Helical Gear Reducer

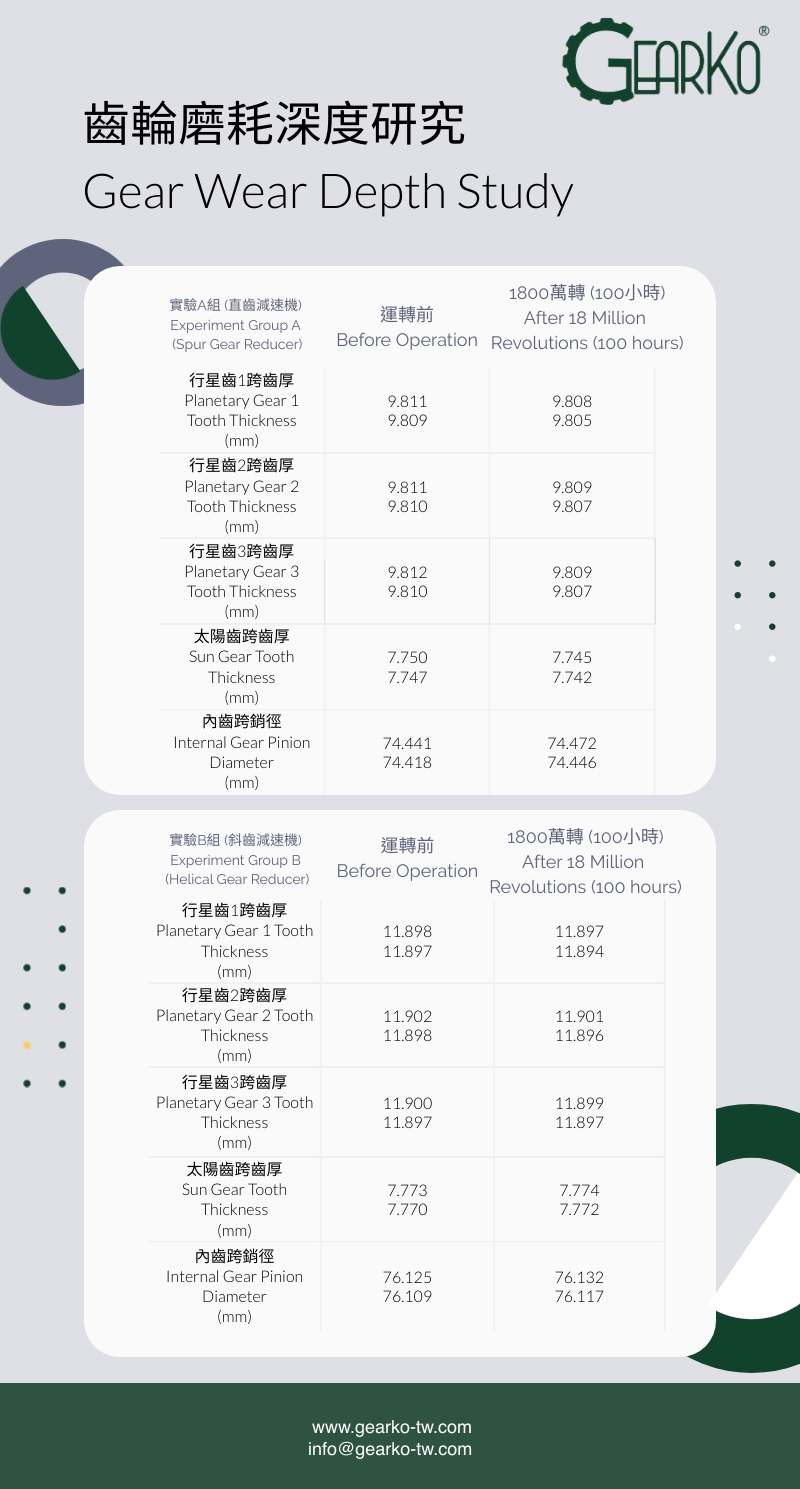

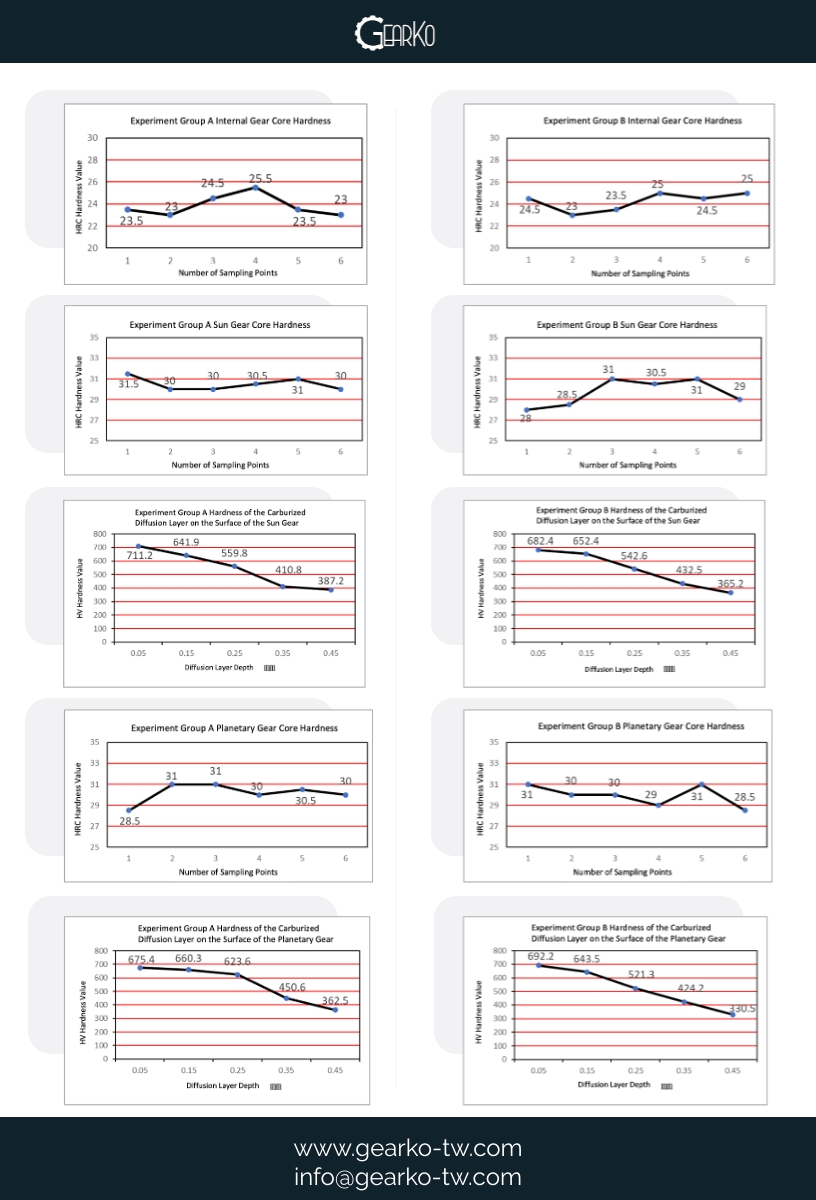

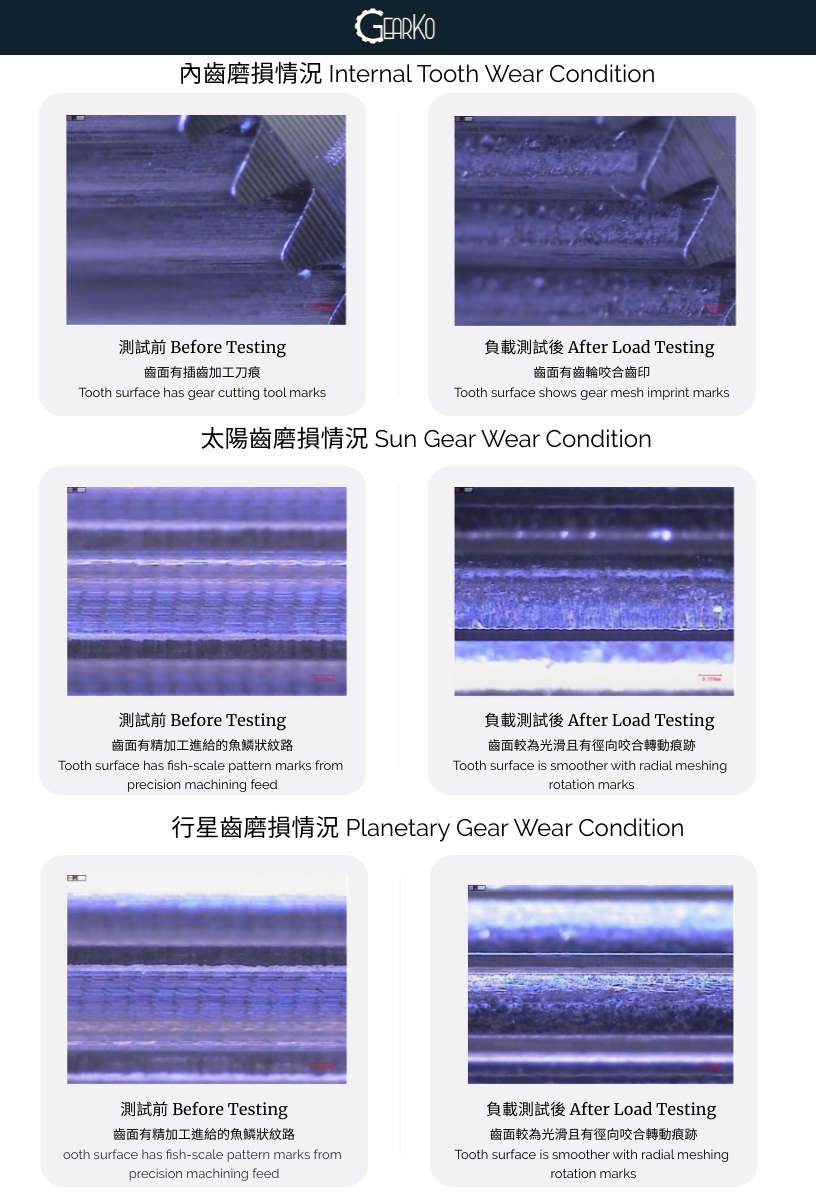

Gearko has conducted an in-depth experimental comparison based on gear durability and load wear. The experiments were divided into two groups: Group A was composed of straight gear reduction machines, and Group B consisted of helical gear reduction machines. Under identical conditions of material heat treatment and surface processing, as well as continuous operational load, the following experimental data was observed and compared.

Precision(Difference) Values for the Gears of Experiment Groups A and B Before and After Operation

|

Precision(Difference) Values |

Experiment Groups A |

Experiment Groups B |

|

Internal Gear Pitch Diameter (mm) |

0.0295 |

0.0075 |

|

Sun Gear Tooth Thickness (mm) |

0.0050 |

-0.0015 |

|

Planetary Gear 1 Tooth Thickness (mm) |

0.0035 |

0.0020 |

|

Planetary Gear 2 Tooth Thickness (mm) |

0.0025 |

0.0015 |

|

Planetary Gear 3 Tooth Thickness (mm) |

0.0030 |

0.0005 |

Based on the results of the above experimental report, under the same test conditions, namely a load of 130N.m and continuous operation reaching 18 million revolutions, the performance in wear precision between straight and helical gear reducers was similar, with no significant difference observed. This outcome underscores the exceptional performance of Gearko planetary gear reducers in terms of durability and reliability, maintaining their precision even under long periods of high-load working conditions. This not only proves the high-quality manufacturing standards of Gearko planetary gear reducers but also demonstrates their excellent wear resistance under extreme working conditions. Therefore, whether for industrial applications requiring high precision or situations demanding high durability, Gearko planetary gear reducers can provide a stable and reliable performance guarantee, standing up to your test.