2023.12.01

The Key to Extending Gear Life: What is Gear Modification?

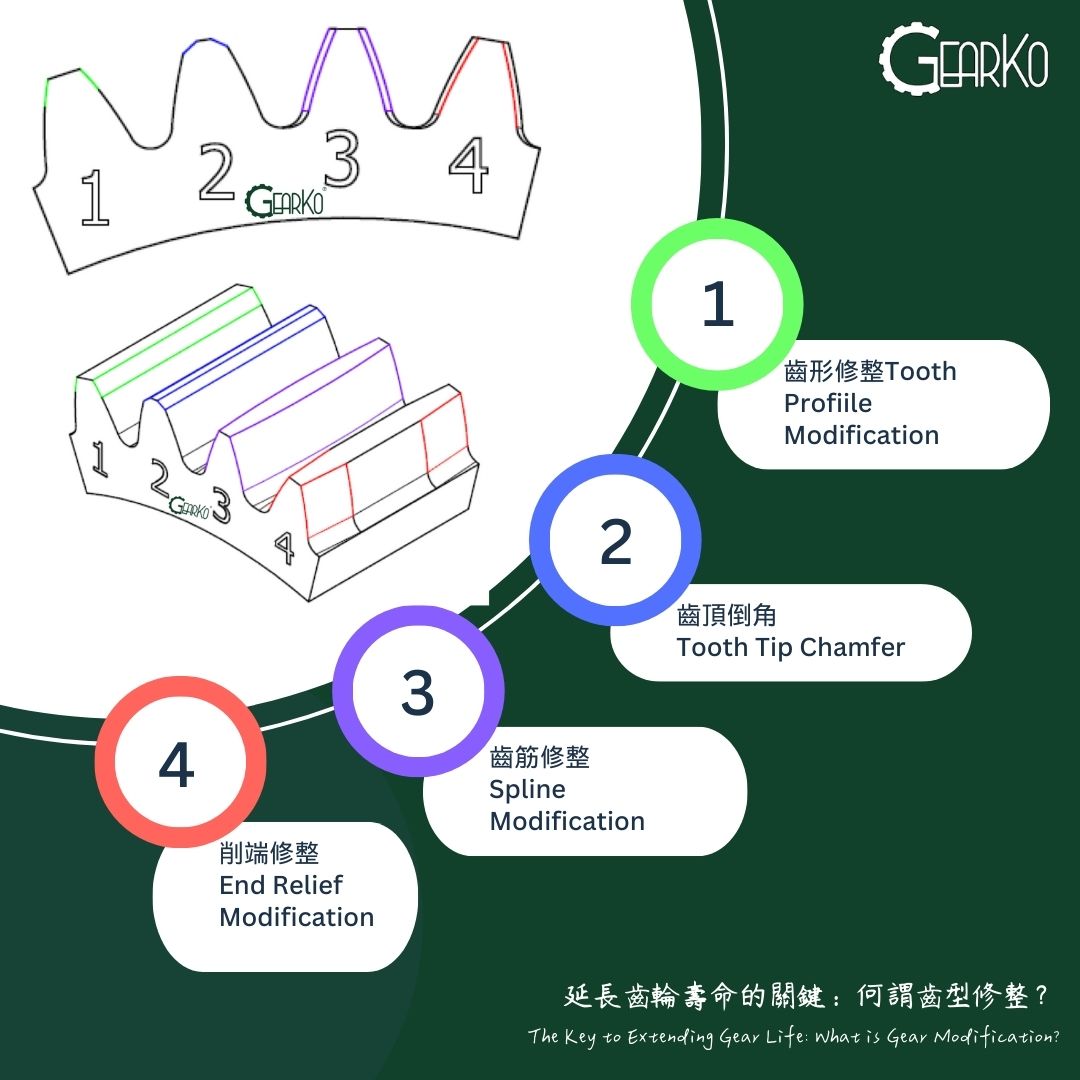

In general gear manufacturing, appropriate gear modifications can prevent operational meshing interference, reduce noise, and extend lifespan. Gear manufacturing modifications typically include (1) tooth profile modification, (2) chamfering of the tooth tip, (3) spline modification, and (4) end relief modification. However, it is important to avoid excessive modification, as this can increase tooth profile errors and adversely affect meshing.

Tooth Profile Modification (refer to the green line in figure 1): Tooth profile modification refers to the overall adjustment of the tooth crown and root. Crown modification is commonly used. When the gear tooth surface deforms under stress, the crown is cut slightly more pointed than the correct involute to avoid interference with the meshing gear, reduce noise, and extend gear life. This process is typically done directly on the gear shaping tool in one operation, especially for producing high-precision, high-geometry gears.

Tooth Tip Chamfering (refer to the blue line in figure 2): Chamfering the gear crown tip helps meshing but reduces the height of tooth contact and consequently the meshing rate, especially in high-contact ratio gears. However, excessive chamfering is generally avoided. The process can be done with gear shaping tools during external diameter hobbing or as a separate operation.

Spline Modification (refer to the purple line in figure 3): Barrel processing involves modifying along the spline direction, with the highest point at the center of the gear spline, tapering towards the ends to form a proper barrel shape. The main purpose is to concentrate stress in the middle of the tooth width to improve transmission efficiency and lifespan. However, excessive barrel processing can reduce the tooth's load-bearing area, negatively impacting gear strength.

End Relief Modification (refer to the red line in figure 4): Similar to spline modification, end relief involves slightly chamfering both ends of the tooth width. The goal is to reduce meshing interference due to geometric errors at the gear ends.

GearKo gear modification for reduction gears is done using single-tooth independent modification combined with high-precision gear CNC equipment, producing gears that balance efficiency, lifespan, noise, and quality above DIN 6 standards. If you have any requirements related to planetary gear reducers, please contact us.