2023.11.03

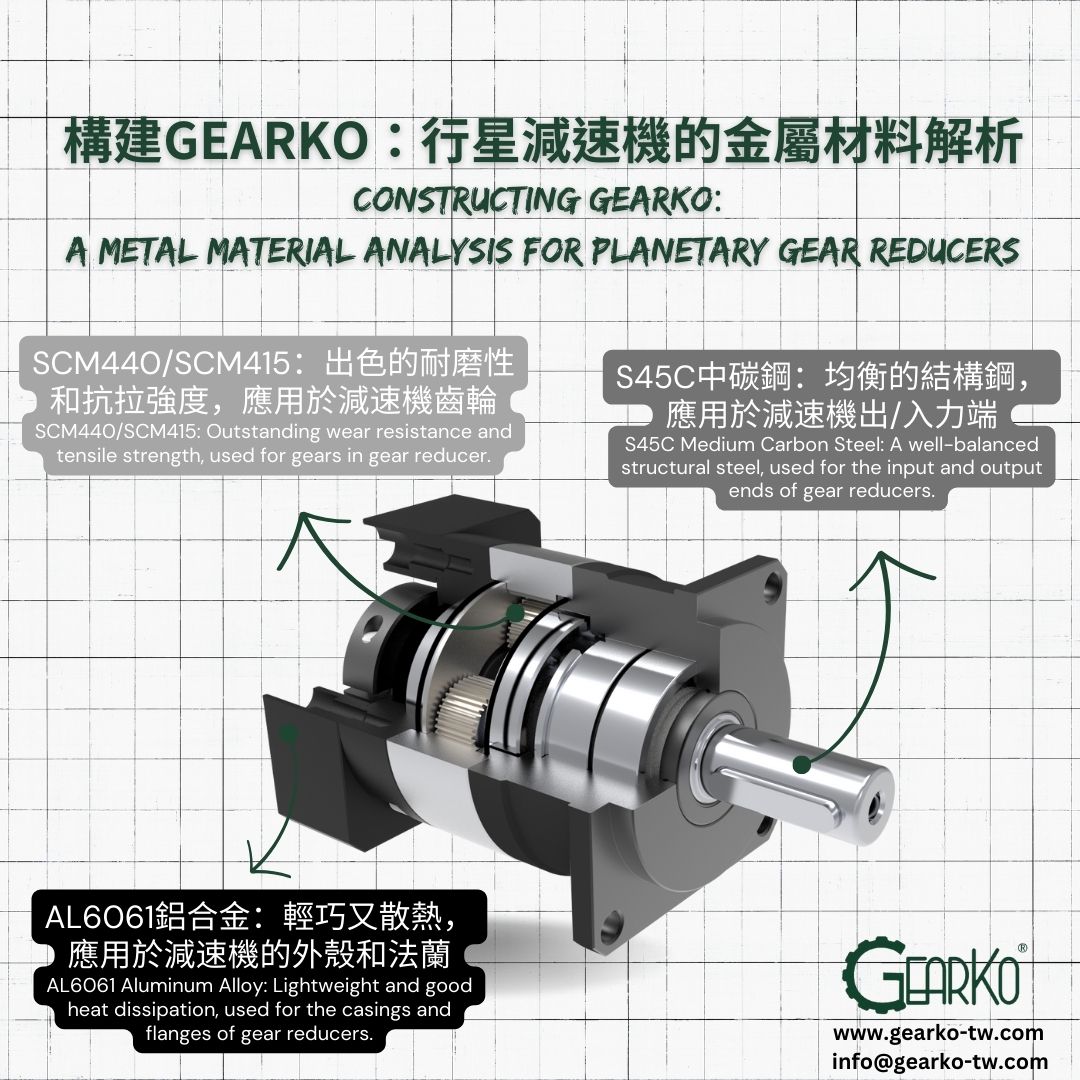

Constructing GearKo: A Metal Material Analysis for Planetary Gear Reducers

GearKo gear reducers employ a variety of top-tier Japanese steel materials to guarantee optimal performance and longevity. The following are the characteristics of these materials:

- S45C Medium Carbon Steel: This is a balanced structural steel with a carbon content ranging from 0.3% to 0.6%. It combines toughness, strength, and malleability. After quenching and tempering, its tensile strength and yield strength are enhanced. GearKo uses it for the input and output shafts of the planetary gear reducers.

- SCM440 Chromium Molybdenum Alloy Steel: Specifically designed for shafts, pillars, and gears with a carbon content of around 0.4%. Post quenching and tempering, its performance surpasses S45C, boasting excellent wear resistance and tensile strength. GearKo particularly chooses this material for the manufacture of reducer gears.

- SCM415 Low Carbon Chromium Molybdenum Alloy Steel: A special wear-resistant steel suitable for parts bearing unique loads, such as main shafts, gears, and pistons. With a carbon content of about 0.15%, its core retains toughness after carburizing, enabling it to withstand greater impacts. GearKo employs this for the gears of the planetary gear reducers.

- AL6061 Aluminum Alloy: A type of 6-series aluminum alloy, primarily containing magnesium and silicon. Not only does it exhibit outstanding machinability, but it also has high weldability and anodizing capabilities. This aluminum alloy is precipitation-hardened. GearKo opts for it as the casing and flange of the planetary gear reducers, offering both lightweight and superb heat dissipation properties.

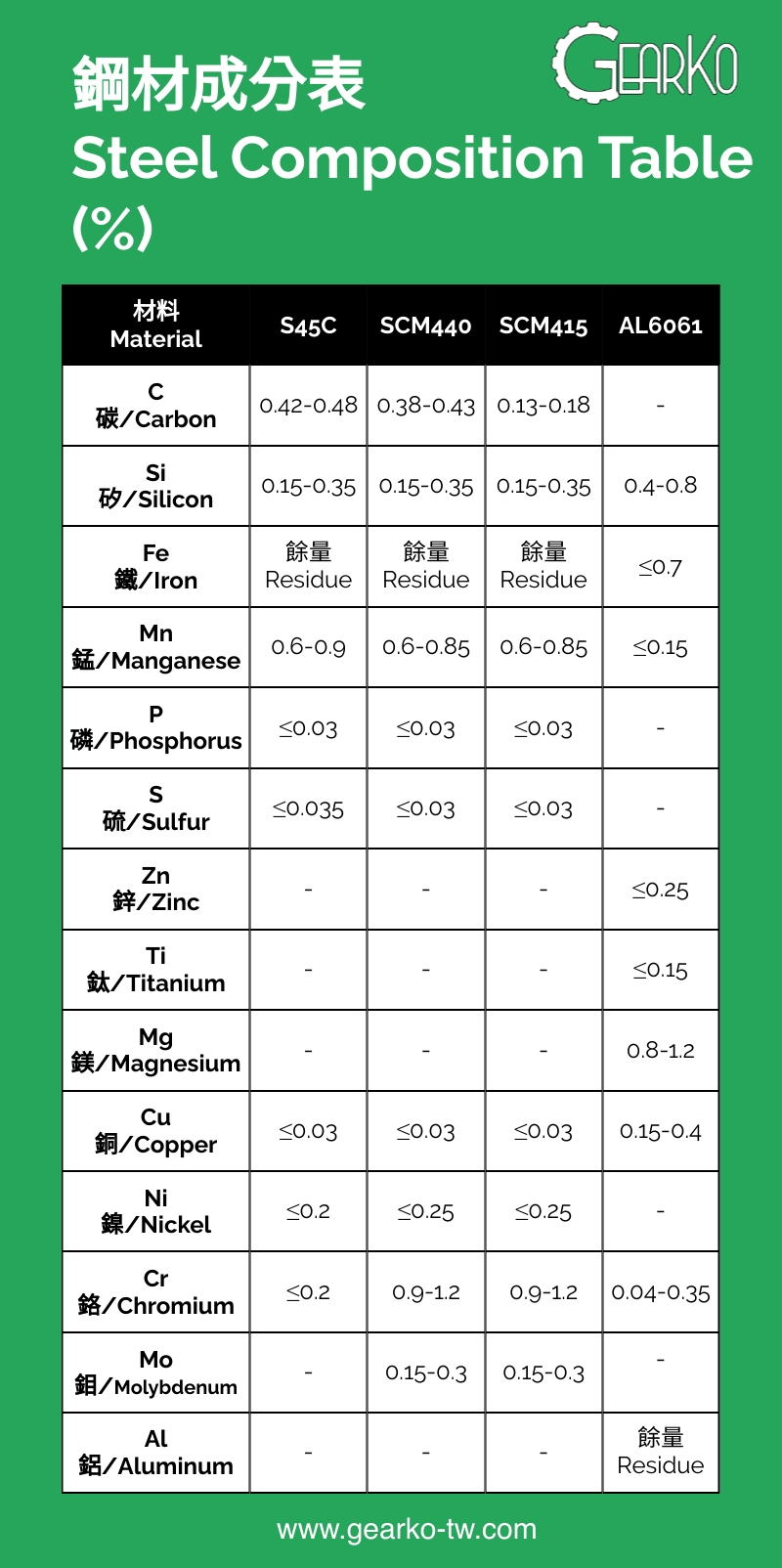

Please refer to the commonly used metal material composition table for planetary gear reducers below:

Glossary:

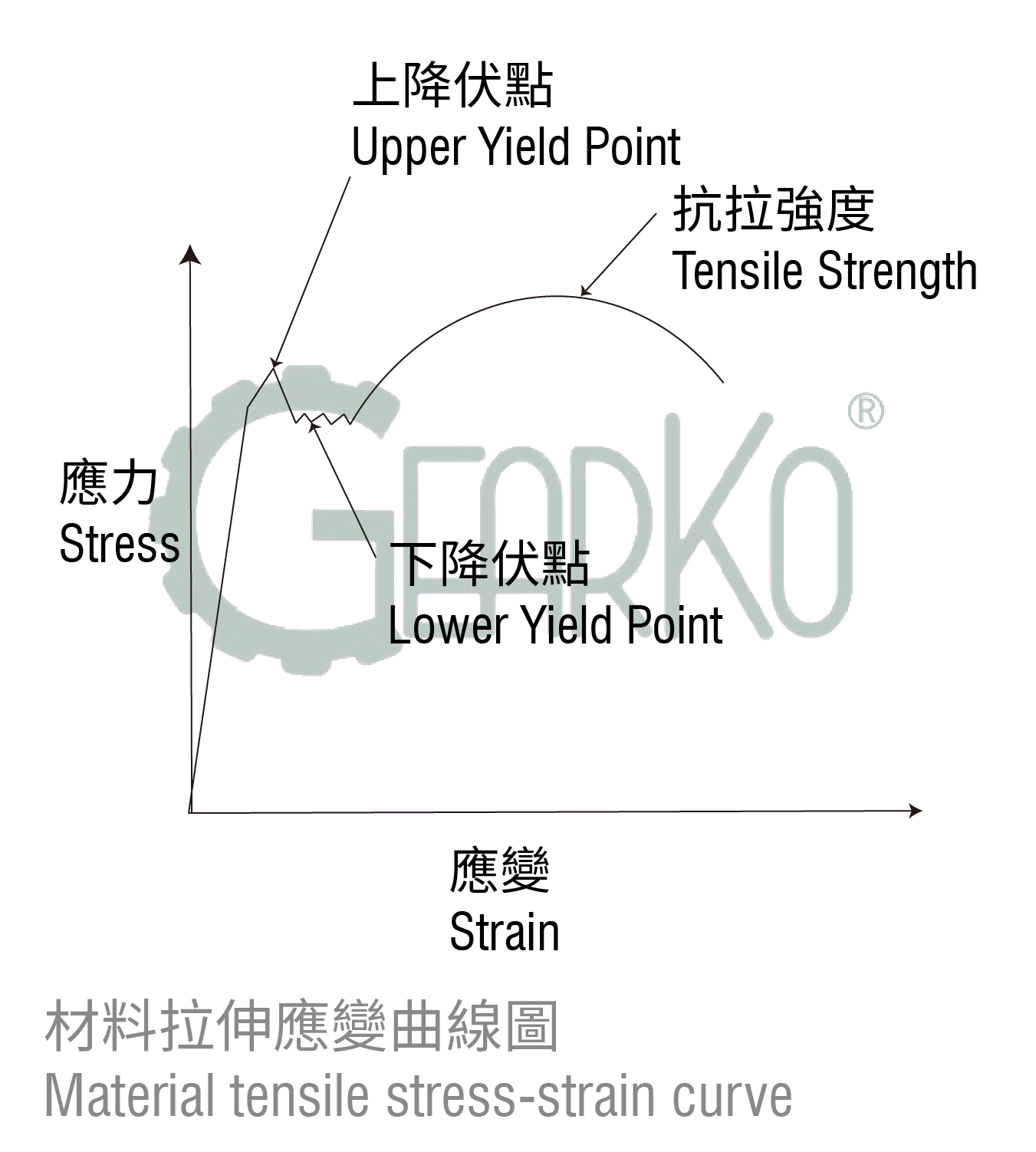

Tensile Strength: Represents the maximum load-bearing capacity of a metal under static tension conditions. It indicates the material's maximum plastic deformation (permanent deformation) resistance. When plastic deformation begins, metal materials exhibit necking, leading to concentrated deformation.

Yield Strength: When a material is subjected to force, if the stress value is below the yield strength, the material's deformation is elastic. Once the load is removed, the material reverts to its original shape. If the force continues to increase, surpassing the yield strength, the material undergoes plastic deformation, resulting in permanent deformation after load removal.

Through meticulous selection and utilization of these high-quality metal materials, GearKo ensures the high efficiency and longevity of our planetary gear reducers. Recognizing the importance of every detail and material choice, we are committed to offering customers the best product solutions. If you have any requirements for planetary gear reducers or wish to learn more about our products, please feel free to contact us.