2023.10.20

Metal Hardness Testing Project - Vickers Hardness Testing Machine (HV)

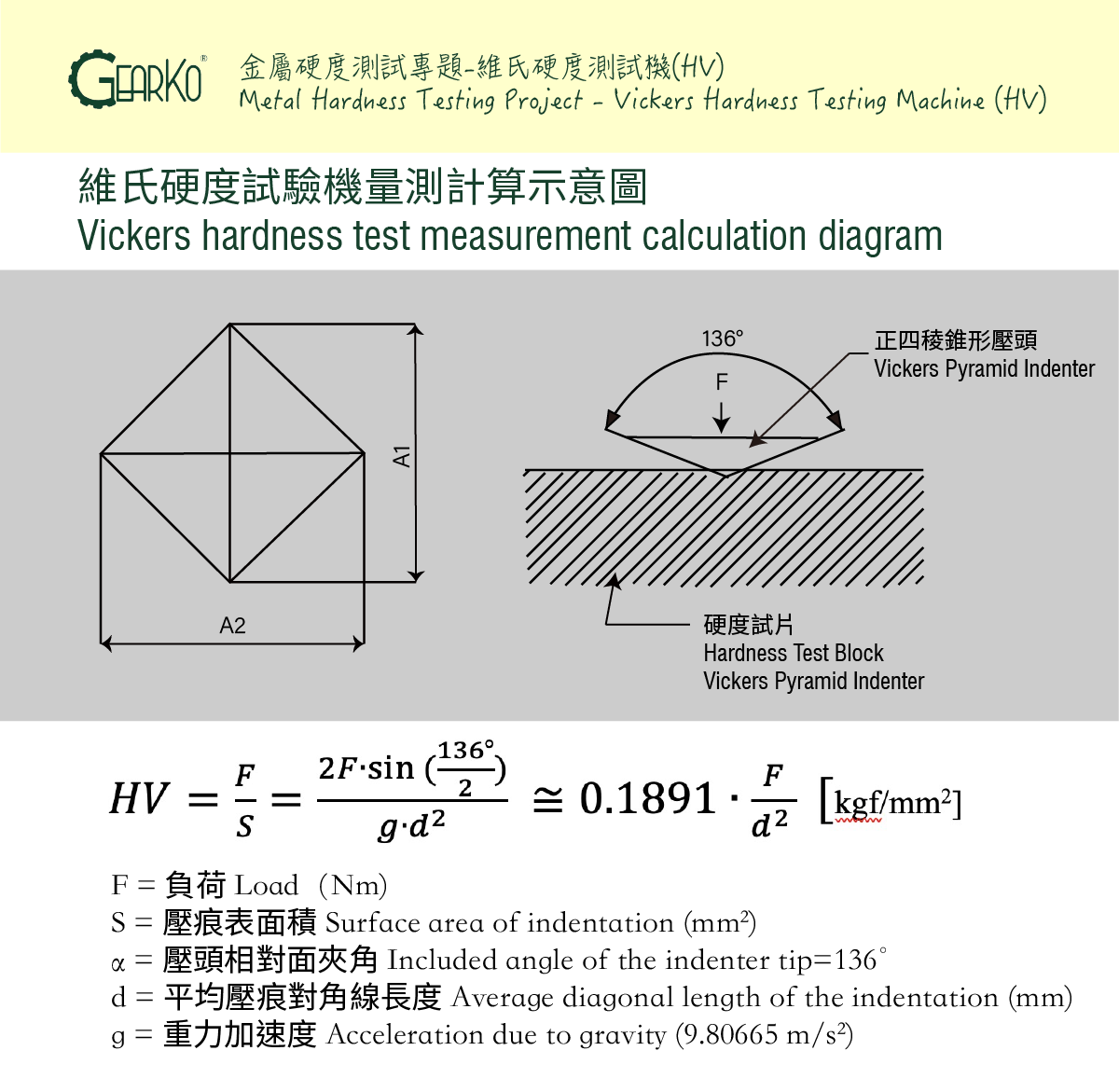

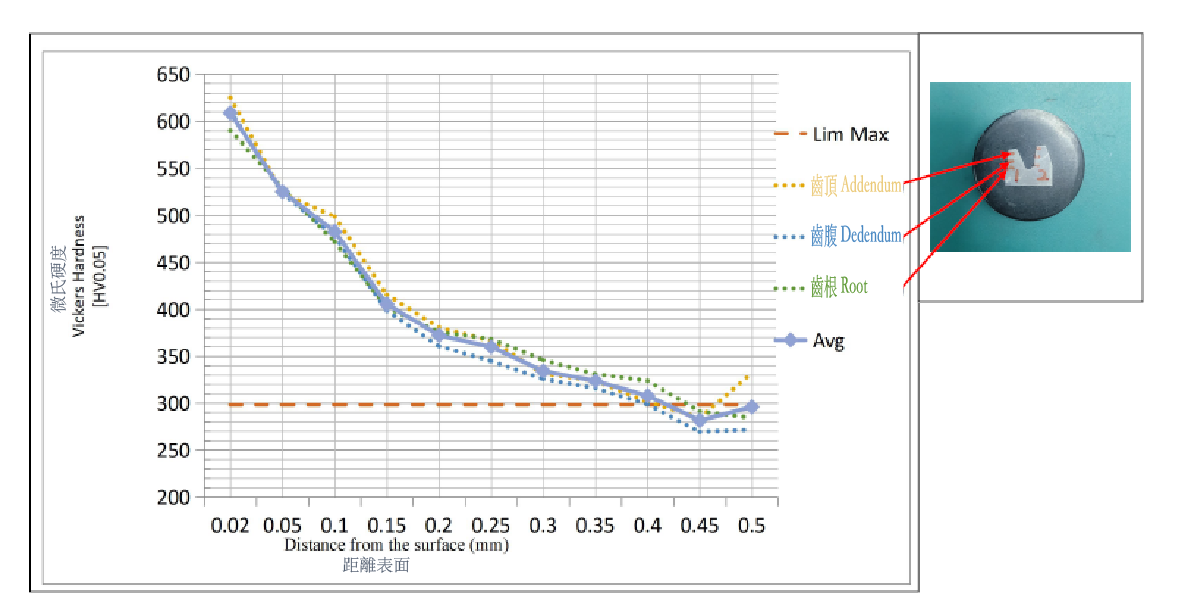

In the planetary gear reducers produced by GearKo, the gear surface hardening process is inspected using the Vickers hardness tester's HV hardness testing standard. A standard pyramidal indenter with an angle of 136° (diamond cone) is used, applying a load of 50g to measure the hardness value of the gear surface (upper and lower wear-resistant surfaces of the gear) and the diffusion layer (tested at every 0.05mm perpendicular to the involute curve inwards). The principle of this measurement method is that after the diamond is pressed into the test material surface under load, it is held for a while and then the load is removed. The average length of the diagonals A1 and A2 of the diamond-shaped indentation formed on the material surface due to the diamond load, as shown in the figure below, is measured. By plugging this average into the formula, the HV hardness value can be obtained.

GearKo is acutely aware of the importance of gear hardness to the overall performance of planetary gear reducers. Therefore, we insist on the highest standards for gear hardness testing. Through precise testing with the Vickers hardness tester, we not only ensure that the gears achieve the desired hardening effect, but also that every part of the gear maintains consistent quality characteristics. We believe that only rigorous testing and continuous effort can produce stable and efficient planetary gear reducers. If you have any needs for planetary gear reducers or other products, please feel free to contact us.