2023.09.01

The Energy-Saving Secret of Gear Reducers with Small Motors-From Cost to Carbon Footprint

In the previous article titled "Mastering the Power of Planetary Gearboxes: Ten Features of Planetary Gear Reducers You Need to Know," we discussed 10 characteristics of planetary gearboxes, one of which is "energy efficiency." In this article, we will delve into the details to understand why using a gearbox can result in energy savings.

To achieve the desired working torque, one can either use a large servo motor with a rated torque greater than the working torque or use a small servo motor combined with a gearbox. This allows the small motor's rated torque to be amplified, as long as it is greater than the working torque, providing sufficient power transmission. The result is that the cost of a small servo with a gearbox is generally less than that of a large servo motor, and the smaller servo motor also consumes less electricity. Below, we will use an example to illustrate how, by using a planetary gearbox, one can not only reduce costs but also effectively save energy.

Example

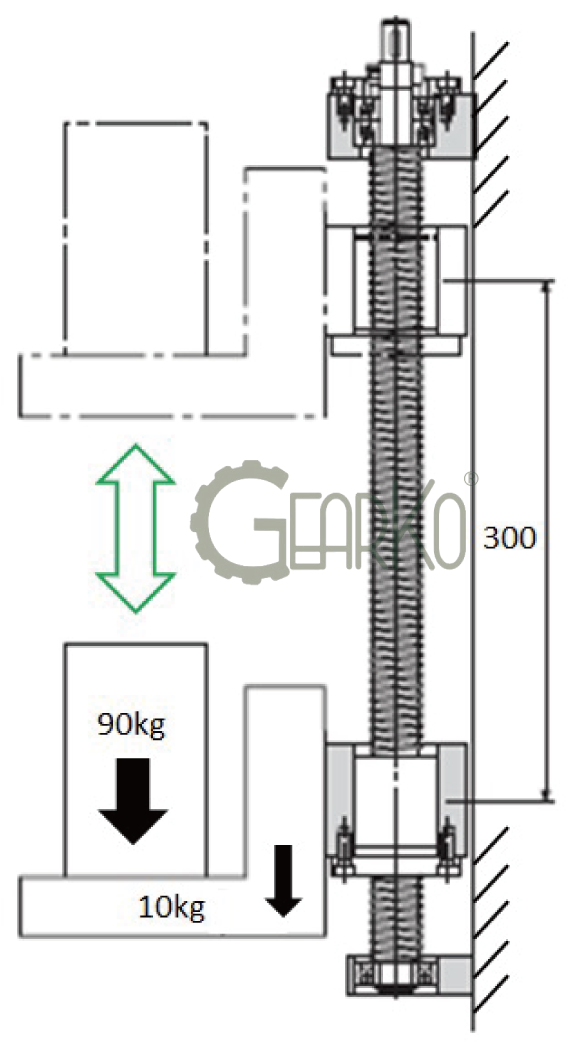

Operational Requirements:

As shown in Figure 1, the screw rises and falls, with a total weight of 100 kg, a travel distance of 300 mm, an acceleration time of 1 second, a constant speed time of 2 seconds, a deceleration time of 1 second, and a stop time of 0.5 seconds. The screw has a lead of 10 mm, a diameter of 20 mm, and a length of 500 mm.

(Figure 1)

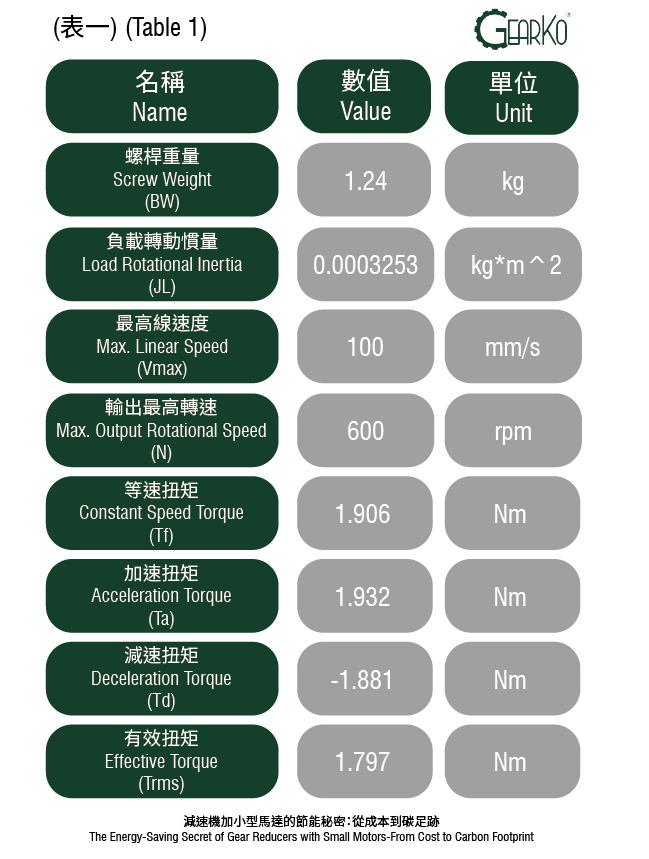

Calculate the required torque and rotational speed for this device: Refer to Table 1 for all the values.

(Table 1)

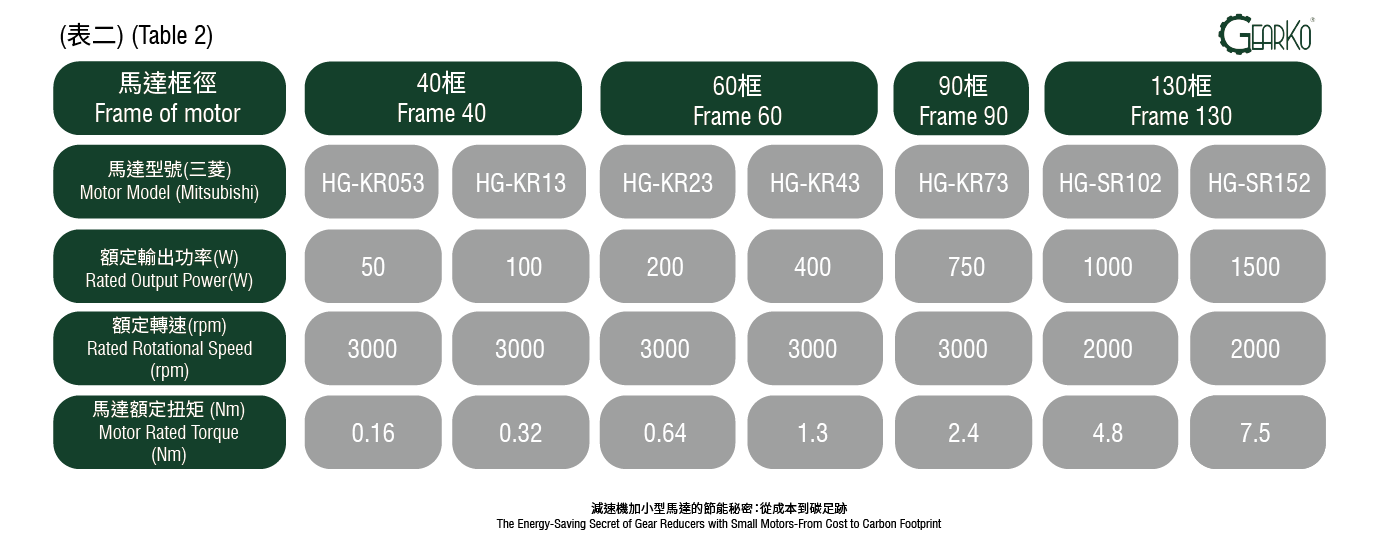

After calculations, the maximum required torque is found to be 1.93 N.m, and the required rotational speed is 600 rpm. Referring to the Mitsubishi servo motor specification table, some data is listed as in Table 2. A 750W motor with an output torque of 2.4 N.m and a rotational speed of 3000 rpm can meet the requirements of a maximum torque of 1.93 N.m and a rotational speed of 600 rpm.

(Table 2)

Improvement Plan:

Input Rotational Speed: 3000 rpm

Output Rotational Speed: 600 rpm

Reduction Ratio i= 5:1

Using a 750W motor (rated torque of 2.4 Nm) with a 5:1 reduction ratio, the required input torque is

2.4/5=0.48 Nm. Leveraging the torque-amplifying feature of the gearbox, any input torque greater than 0.48 Nm will be sufficient. Referring to Table 2, a 200W motor could replace the 750W motor.

The 200W servo motor (rated torque of 0.64 Nm), when paired with a GearKo 60-frame 5:1 gearbox (rated torque of 55 Nm), will have an output torque of 0.64×5=3.2 Nm. This is greater than the required torque of 1.93 Nm, and it is less than the gearbox's rated torque of 55 Nm, making it a safe choice for use. If the output torque exceeds the gearbox's rated torque, it would be considered an overload and could shorten the gearbox's lifespan.

The motor's rotational speed drops from 3000 rpm (with a 5:1 ratio) to 600 rpm, meeting the required rotational speed of 600 rpm.

Estimated Cost Expenditure:

- Table 3 shows the annual electricity costs for motors of various power ratings under the same time conditions.

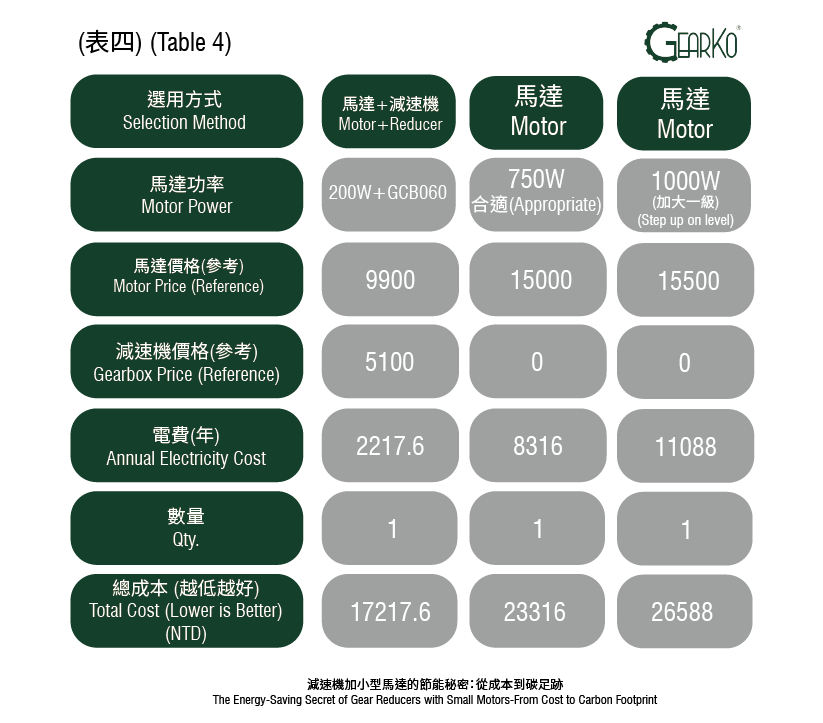

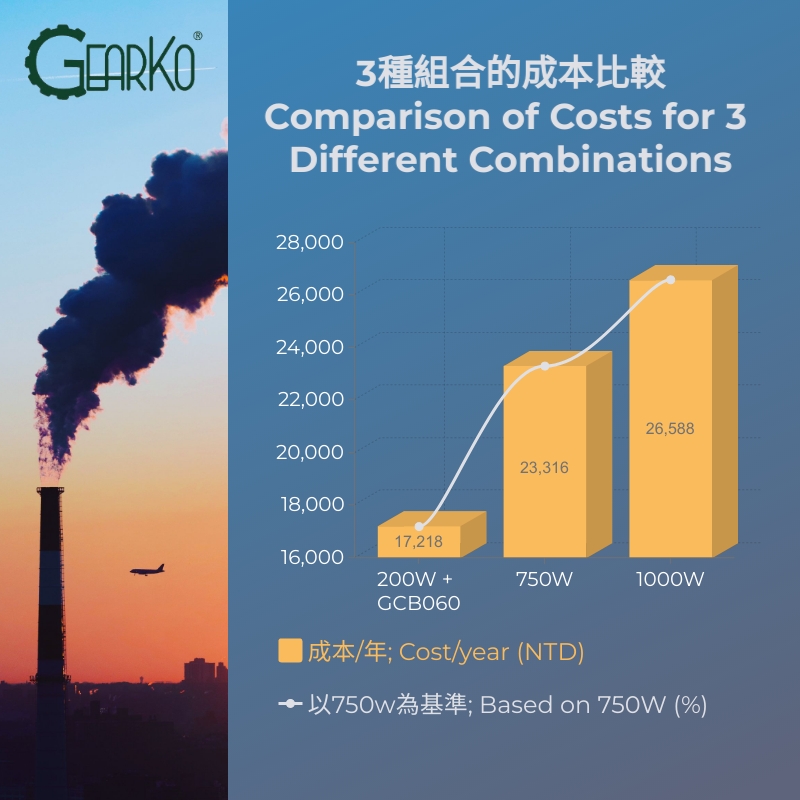

- From Table 4, one can observe the accumulated annual cost for three different power combinations that are under consideration.

3. From the analysis in Tables 5 and 6, it is evident that there is a significant difference in the annual cost expenditure among these three selected power combinations.

(Table 5)

|

Motor Power |

200W+ Frame 60 Reducer |

750W(Appropriate) |

1000W(step up one level) |

|

Annual Cost Expenditure (NTD) (Lower is Better) |

17217.6 |

23316.0 |

26588.0 |

|

Compared to the Suitable Motor as a Benchmark (%) |

73.8% |

100.0% |

114.0% |

(Table 6)

Result Analysis:

From Tables 5 and 6, it is evident that by choosing a 200W motor along with a 60-frame gearbox, the cost is reduced by 26.2%. This configuration only requires 73.8% of the cost of the original 750W motor to meet the operational requirements.

Energy Conservation and Carbon Reduction:

Energy conservation and carbon reduction have become globally recognized issues. In Taiwan, the government is regulating corporate carbon emissions through carbon inventories and cap-and-trade systems. There are also plans to accelerate amendments to the Climate Change Response Act to levy a "carbon fee" on high-emission enterprises. For individuals, various policies have been introduced, such as offering discounts for using reusable cups, to encourage public participation in environmental actions.

In the above example, we only compared one 750W servo motor with a combination of one 200W servo motor and a 60-frame gearbox. The data can be referred to in Table 7.

(Note: The carbon emission coefficient for electricity in the year 111 of the Republic Era [2022], as announced by the Energy Bureau of the Ministry of Economic Affairs, is 0.495 kg CO2e per kWh.)

|

Category |

Qty. (PCS) |

Annual Electricity Consumption (kWh) |

Annual Carbon Emissions (kg) |

|

750W Servo Motor |

1 |

1188 |

588.06 |

|

200W Servo Motor + Frame 60 Gearbox |

1 |

316.8 |

156.816 |

(Table 7)

As shown in Table 7, the annual carbon emissions from a 750W servo motor are 3.75 times that of a 200W servo motor combined with a 60-frame gearbox. And this is just for a single motor.

Conclusion:

Due to the torque-amplifying feature of gearboxes, they can magnify small torques, enabling motors to drive loads larger than their original ratings. This allows the use of lower-power motors to replace higher-power ones. If you have similar application needs and have any questions regarding the combination and usage, feel free to contact us at any time. Calls or emails to GearKo are welcome.