2023.09.08

Metal Surface Treatment Topic: The Role of Anodizing in Planetary Gear Reducers

What is Anodizing Treatment?

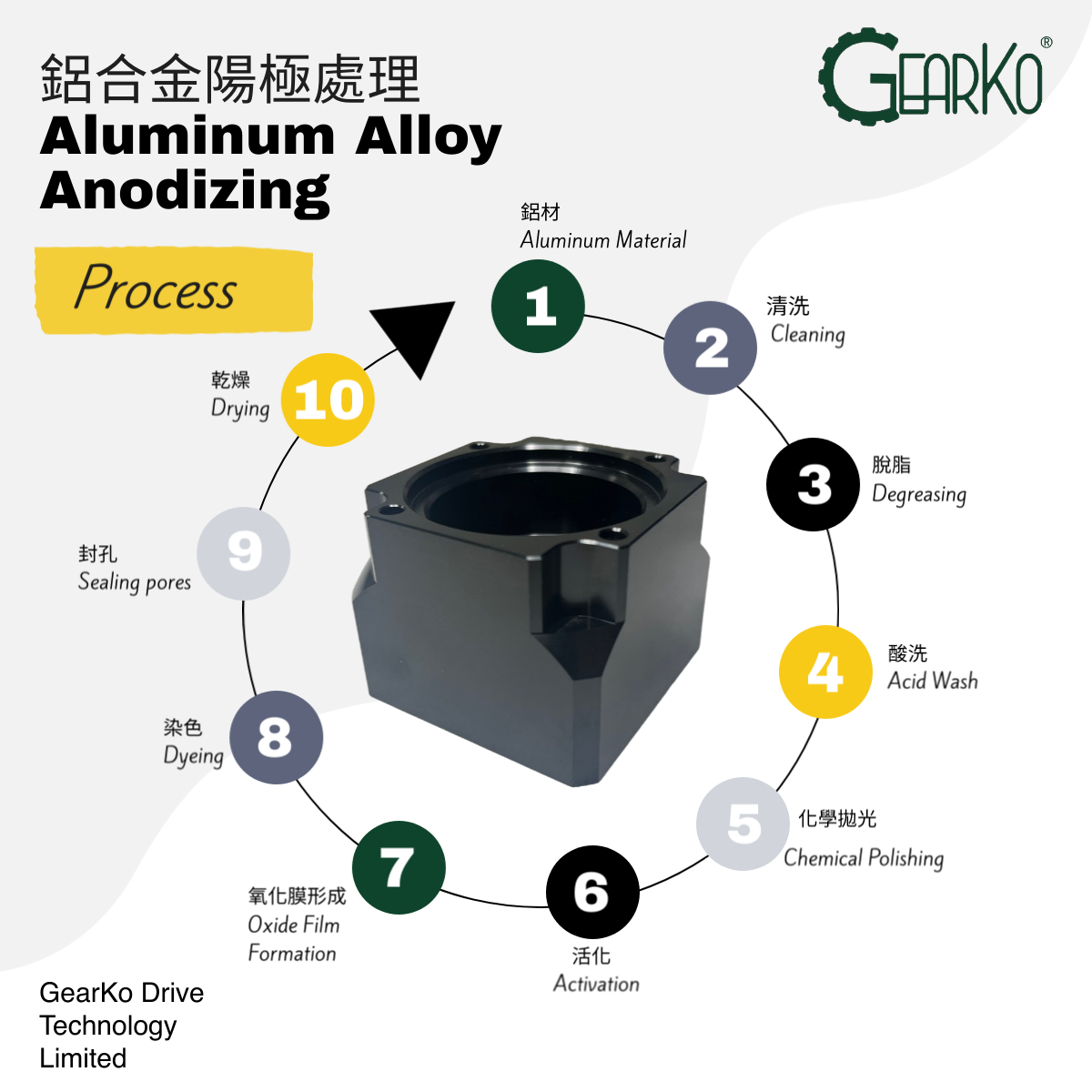

Anodizing is a type of electrolytic passivation process for surface treatment. Generally, the surface of aluminum alloys easily oxidizes when exposed to the environment. While the self-generated oxide layer does offer some passivation, it can gradually peel off with prolonged exposure, losing its protective capabilities for the aluminum substrate. Anodizing takes advantage of the alloy's tendency to oxidize by applying voltage and current. The part to be treated serves as the anode, and a corrosion-resistant material acts as the cathode. Through electrochemical methods, the oxidation layer is quantitatively and forcibly controlled. The aim of anodizing is to prevent further oxidation of the aluminum material while enhancing its mechanical properties, abrasion resistance, corrosion resistance, and insulating capabilities. Another objective is to improve aesthetics through various chemical reactions that produce different colors.

GearKo Planetary Gear Reducers

GearKo produces planetary gear reducers whose non-gear parts are made from 6061 precipitation-hardened aluminum alloy, treated with T6. These parts are highly machinable and possess excellent mechanical properties, weldability, corrosion resistance, and toughness. They do not easily deform after processing and are easy to polish. The materials combine high strength with low weight. The exterior surface treatment uses anodizing, and the standard specification is glossy black, offering excellent texture. If you require a large number of customized colors for your planetary gear reducers, please contact GearKo in Taiwan for inquiries.

Glossary

T6: The T6 treatment for aluminum alloys involves solution heat treatment followed by artificial aging. This process eliminates the need for cold working (forging, pressing) and results in superior strength. It significantly improves mechanical properties and dimensional stability through precipitation heat treatment.

Further Reading:

Metal Surface Treatment Topic - Ionic Nitriding Treatment (Ion nitriding)

Metal Surface Treatment Topic - Carburizing Treatment

Metal Surface Treatment Topic- Nitriding vs. Carbonitriding Surface Heat Treatment Comparison

Metal Surface Treatment Topic: Environmental Benefits and Advantages of Electroless Nickel