2023.07.07

Metal Surface Treatment Topic - Ionic Nitriding Treatment (Ion nitriding)

Ion nitriding, also known as plasma nitriding, is widely used in precision industries such as military, medical, and automotive as a crucial process for strengthening metal surfaces. This process utilizes high-purity argon, hydrogen, and nitrogen gases to ionize argon gas in a vacuum, generating plasma glow discharge to heat and activate the metal surface. Subsequently, by continuously bombarding the part’s surface with ionized nitrogen gas, a surface-nitrided layer is formed. This process is applicable to materials like carbon steel, alloy steel, stainless steel, and titanium alloys. Ion nitriding treatment improves surface hardness, resulting in high hardness, wear resistance, fatigue strength, and corrosion resistance.

GearKo planetary gearboxes employ ion nitriding (plasma nitriding) for heat treatment of their small module gears, eliminating the need for secondary gear grinding while maintaining high precision. Through precise control of the diffusion layer, the formation of surface compound layers, including the white layer, can be reduced or eliminated, ensuring the gears maintain wear resistance and toughness. With the advantage of ion-nitrided gears, GearKo planetary gearboxes offer high-quality performance and reliability, enduring extreme environmental conditions. Whether in military equipment, medical devices, or the automotive industry, GearKo planetary gearboxes demonstrate outstanding durability and dependability, making them a trusted choice.

Noun Definitions:

White Layer (Compound Layer): It is a hard and wear-resistant layer formed on the metal surface during ion nitriding(plasma nitriding). It is denser than gas nitriding and is typically found in pressure-loaded components. The generation of the white layer should be minimized to prevent cracking under pressure, thereby reducing the component's lifespan. Think of it as a layer of chocolate coating on an ice cream cone.

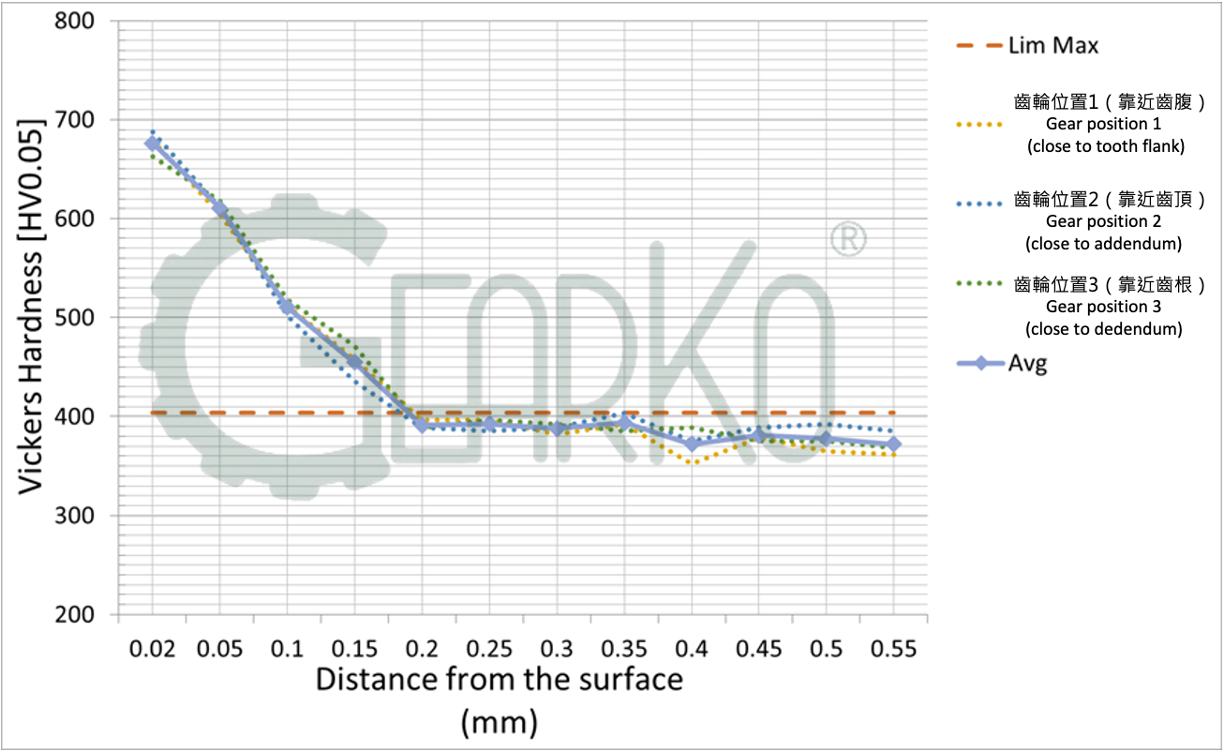

Please refer to Figure 1 for the hardness diffusion layer of the gear made from SCM440 material (marked with a red cross) after ion nitriding.

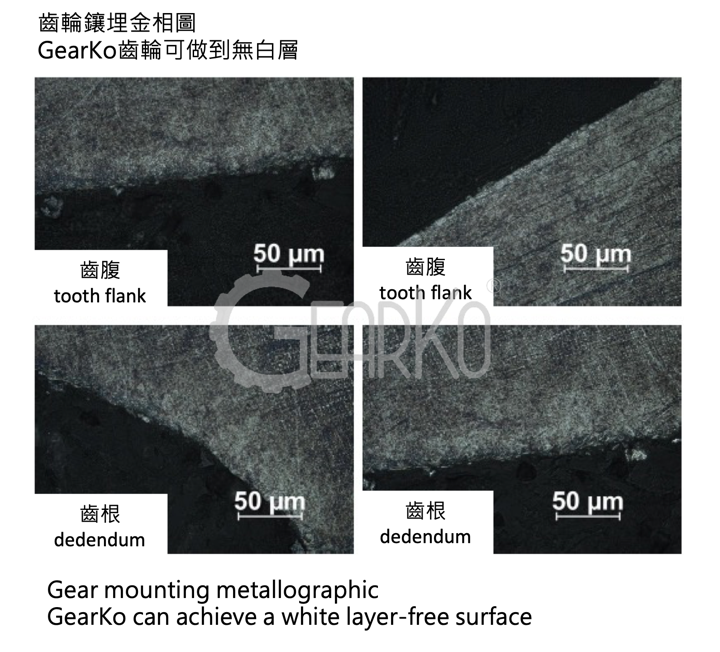

Figure 2 shows the gear mounting metallographic after ion nitriding, demonstrating GearKo’s ability to achieve a gear without a white layer.

Further reading:

Metal Surface Treatment Topic - Carburizing Treatment

Metal Surface Treatment Topic- Nitriding vs. Carbonitriding Surface Heat Treatment Comparison

Metal Surface Treatment Topic: Environmental Benefits and Advantages of Electroless Nickel

Metal Surface Treatment Topic: The Role of Anodizing in Planetary Gear Reducers