2024.07.05

Causes and Solutions for Overheating in Planetary Gear Reducers: Efficient Cooling and Maintenance Guide

Planetary gear reducers play a crucial role in matching speed and transmitting torque between the prime mover (motor) and the working mechanism. They are relatively precise mechanical devices designed to reduce speed and increase torque. Due to their diverse types and models, different planetary gear reducers are suitable for various working environments. For a more detailed understanding of planetary gear reducers, you can refer to the GearKo website article, "Choosing the Right Gearbox: A Comprehensive Guide to Various Types of Gear Reducers."

Planetary gear reducers are characterized by their compact size and high torque transmission. Designed and manufactured based on modular principles, they offer numerous combinations, installation forms, and structural solutions. With fine transmission ratio gradations, they meet different working conditions and achieve electromechanical integration. Precision planetary gear reducers are highly efficient, low in energy consumption, and superior in performance. However, as temperatures continue to rise, the issue of overheating in planetary gear reducers becomes increasingly prominent. Below, we will explore the main factors causing overheating in planetary gear reducers.

Three Main Causes of Overheating in Planetary Gear Reducers

1. High Speed:

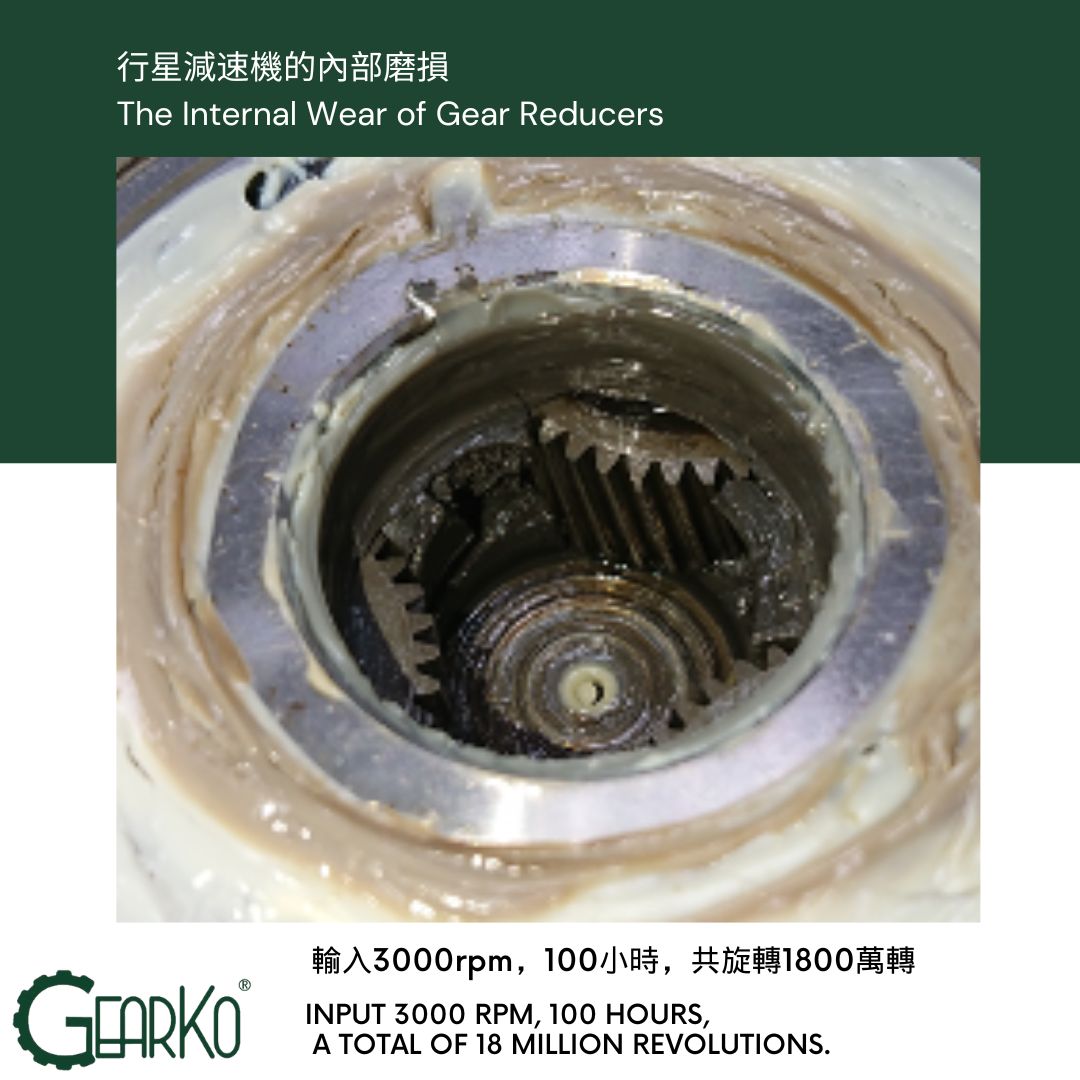

When the mechanical speed of the equipment increases, internal wear in the planetary gear reducer also rises, exacerbating heat generation.

2. High Input Power:

The greater the input power, the more significant the friction effect inside the planetary gear reducer, generating a large amount of heat.

3. High Environmental Temperature:

The environmental temperature affects the planetary gear reducer's temperature through conduction, convection, and radiation. For example, if the motor bearings lack lubrication, friction increases, causing a temperature rise; a jammed motor increases current and temperature; worn bearings or damaged cages can also lead to overheating. Therefore, timely inspection of easily worn parts and replacement of worn bearings are crucial operations for extending equipment lifespan.

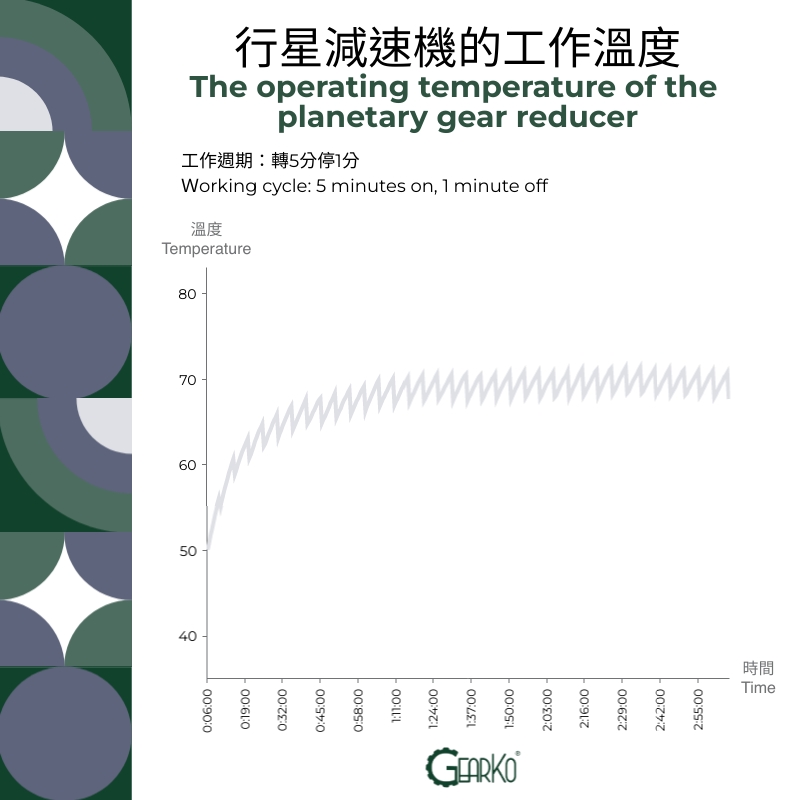

The operating temperature range for GearKo Taiwan's planetary gear reducers is -20~90°C. Generally, the longer the planetary gear reducer operates, the higher the temperature. When it reaches a certain level, cooling treatment is required. Therefore, the setting of the working cycle directly affects the working temperature. Regular temperature checks and records are essential maintenance tasks.

The maximum temperature for a planetary gear reducer is 90°C. Once this temperature is exceeded, it can impact internal components. In high-temperature conditions, the temperature rise is more apparent. Maintenance and lubrication of the planetary gear reducer are also necessary. For low-temperature conditions (e.g., -20°C), it is recommended to gradually raise the machine temperature to above zero before carrying out load operations.

Applications of Planetary Gear Reducers

Planetary gear reducers are widely used in various fields, especially in low-speed, high-torque transmission equipment. With the continuous development of high-efficiency planetary gear reducer industries, more industrial equipment is using motor + planetary gear reducer combinations as transmission devices. The limit working temperature of the insulation material in the motor windings varies depending on the material. If the temperature continuously exceeds or approaches the limit working temperature, the aging of the insulation material will accelerate, significantly shortening its lifespan. Thus, temperature is a key factor affecting the lifespan of transmission devices.

Insulation Material Temperature Grades:

|

Heat Resistance Grade |

Temperature (℃) |

|

Y |

90 |

|

A |

105 |

|

E |

120 |

|

B |

130 |

|

F |

155 |

|

H |

180 |

Conclusion

Regular equipment maintenance and daily usage records can help observe changes in the equipment, allowing you to develop the most suitable maintenance plan. By enhancing equipment management and maintenance, promptly addressing issues, you can ensure the normal operation of planetary gear reducers, extend equipment lifespan, and improve production efficiency.

If you encounter any issues with the use of planetary gear reducers, please feel free to contact us. We are dedicated to resolving your problems. Please reach out to GearKo Taiwan through phone or email.