2023.08.08

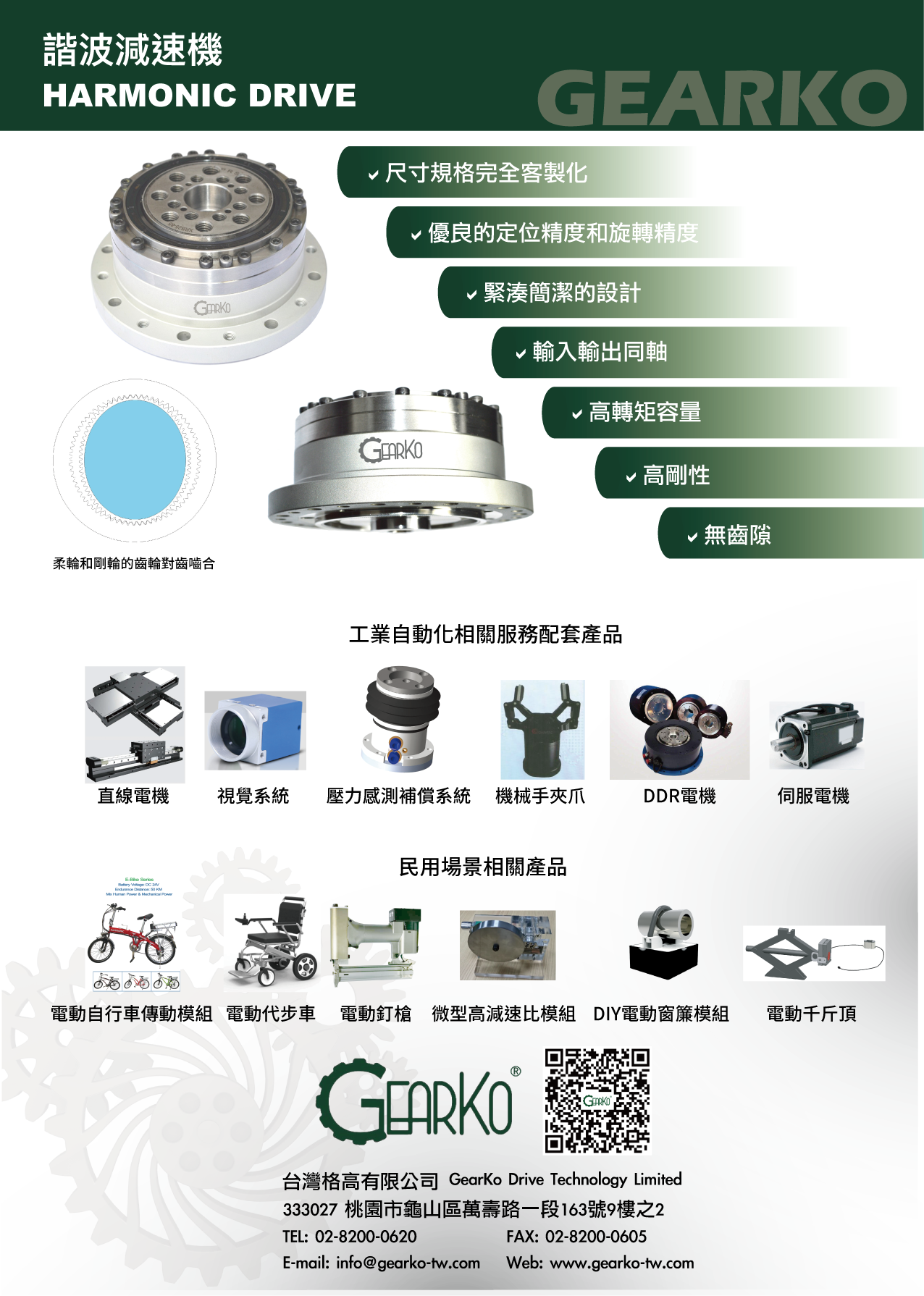

Introduction to GearKo HM Series-Harmonic Gear Reducers

Harmonic gear reducers are an advanced mechanical device specifically designed for precise speed control and torque management. Using unique harmonic drive technology, they have become the ideal choice for automation, robotics, precision machining, and other high-end industrial applications. With exceptional precision, efficiency, high-load torque, lightweight design, as well as long life and low wear characteristics, they are highly regarded. Taiwan's GearKo HM series of harmonic gear reducers, as the pioneer product in this field, with their advanced engineering and quality materials, have become the first choice for many industrial customers.

The GearKo HM series of harmonic gear reducers from Taiwan were developed over five years as an exclusive product for automation. Through a unique conjugate tooth design, they possess exceptional rigidity, effectively resisting high rotational inertia. Its core component, the flexspline, uses durable Japanese imported steel, resistant to fatigue and low in wear. The 6-series aluminum casing is aesthetically pleasing, reducing weight, and enhancing equipment efficiency.

As a special type of gear differential reducer, the core components of a harmonic gear reducer include the flexspline, rigid gear, wave generator, flexible bearing, and cross roller bearings, etc. Its working principle is complex, involving the interaction of the elliptical wave generator and the rigid gear, achieving precise reduction motion. Simply put, the wave generator is elliptical, fitted into the flexible bearing and flexspline, making them elliptical as well. The flexspline is a thin-walled external gear that continuously deforms with the rotation of the wave generator. The rigid gear is a hollow ring internal gear that does not deform, usually having two more teeth than the flexspline. Once the deformed flexspline and wave generator are fitted into the rigid gear, the long axis teeth of the flexspline mesh with the rigid gear teeth, while the short axis teeth disengage. When the motor drives the wave generator to rotate, the ellipse rotates to form a mechanical wave, and the flexspline changes shape with the wave, constantly changing the position of the long and short axes, causing the meshing teeth to continually engage and disengage. Since the flexspline and rigid gear have different numbers of teeth, they generate relative rotation, achieving the purpose of reduction movement. Since the harmonic gear reducer only has two gears and belongs to a single-stage drive, the meshing teeth of the rigid gear and flexspline are far more than ordinary gears, hence it has high precision, high reduction ratio, high torque load, low weight, and small volume, making it the unrivaled category for high precision requirements.

Whether you need high precision, customized design, low noise and temperature rise, or are pursuing cost-effectiveness, in the field of automation, Taiwan's GearKo HM series of harmonic gear reducers will provide excellent performance and reliable motion control solutions for your application. Choose GearKo to enjoy leading harmonic reduction technology and outstanding customer service.