2023.07.14

Metal Surface Treatment Topic - Carburizing Treatment

The carburizing process can be traced back over 2000 years in China. Initially, solid carburizing was employed, and liquid and gas carburizing methods emerged and gained widespread application in the mid-20th century.

Solid Carburizing: This method involves placing the workpiece and solid carburizing agents (such as wood, coal, and other accelerants) in a sealed heating furnace. The furnace is then heated to the carburizing temperature and kept at that temperature for a certain period. This allows the active components in the solid carburizing agents to decompose into carbon atoms, which infiltrate the crystal structure gaps on the workpiece surface. This is one of the earliest methods of carburizing.

Liquid Carburizing: Liquid media are used in this carburizing process. Some liquid media contain cyanides, which are highly toxic and require careful handling. Liquid carburizing is suitable for medium and small-sized workpieces. The liquid media heat up quickly, have uniform quality, and are easy to control. The advantages of this method include its simplicity, flexibility, and the development of non-toxic salt bath carburizing.

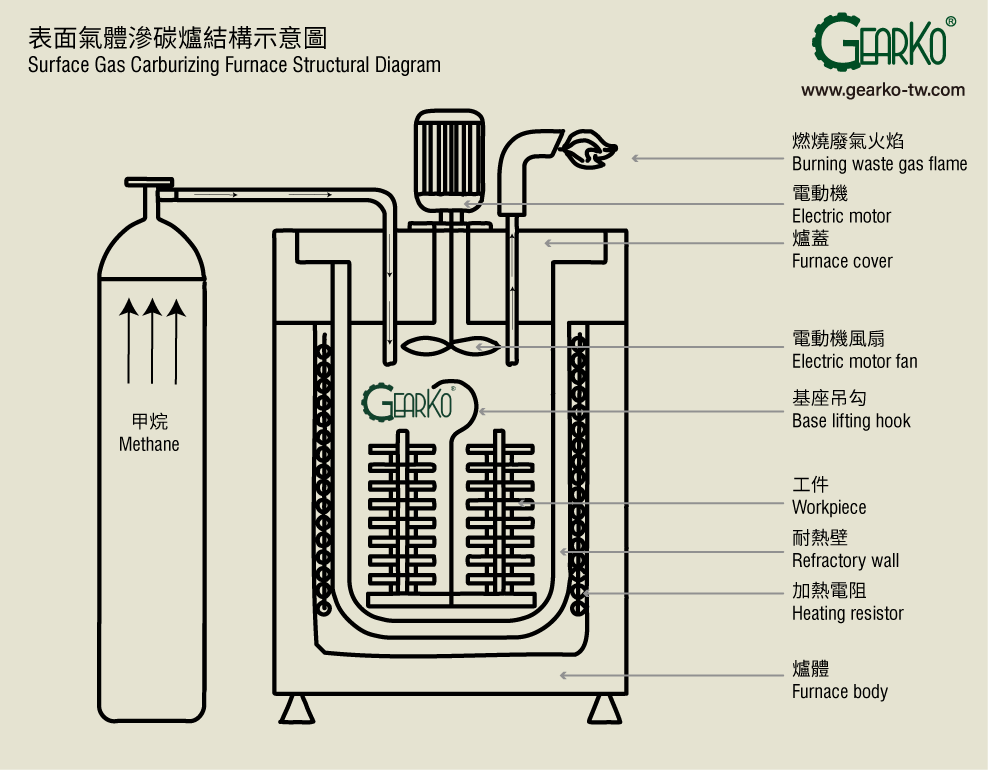

Gas Carburizing: In gas carburizing, the workpiece is placed in a sealed carburizing furnace, and carburizing gas (such as methane or ethane) or liquid carburizing agents (such as kerosene, benzene, alcohol, or acetone) are introduced. Under high-temperature heating, the carburizing agent decomposes and releases active carbon atoms, which infiltrate the crystal structure gaps on the workpiece surface.

Surface carburizing treatment has been applied to surface hardening of low-carbon steel for a considerable period of time. The longer the carburizing time and the higher the temperature, the deeper the carbon diffusion layer, typically ranging from 0.4 to 1.5 mm. The carburized hardness can reach HRC58-63. This process is mature, stable, and commonly used for surface carburizing hardening of low-carbon steel with a carbon content of approximately 0.1-0.25%. The main alloying elements in carburized steel are chromium, manganese, titanium, vanadium, etc., which mainly serve to improve hardenability.

Due to its surface hardness, wear resistance, good core toughness, and excellent impact resistance, carburized steel is often used in the manufacturing of low-carbon chromium-molybdenum alloy steel for gear materials. For example, in the heat treatment of gear surfaces, a hardness of HRC 55-60 is typically required, with a carburizing diffusion layer of approximately 0.2-0.4 mm. After rough machining, the raw material undergoes surface gas carburizing treatment. The gear is placed in a furnace (refer to the schematic diagram of the surface gas carburizing furnace below) and heated to 850-950°C, while methane gas is introduced. At high temperatures, carbon atoms are released and infiltrate the steel surface. Subsequent quenching and tempering processes result in a surface with high carbon steel strength, hardness, and wear resistance, while retaining the original physical toughness in the core of the steel. This achieves the desired properties of a hard exterior and a tough interior for the gear. However, due to the high-temperature characteristics, the gear material may experience stress release and crystal structure transformation. It is necessary to precision grind or roll the gear teeth to achieve the desired dimensions and accuracy before use.

In GearKo’s planetary gearbox, the surface carburizing process is used within a fixed module range. High-quality alloy steel is selected as the material to achieve optimal wear resistance and impact toughness. If you have any requirements for planetary gearboxes, please feel free to contact us.

Further Reading:

Metal Surface Treatment Topic - Ionic Nitriding Treatment (Ion nitriding)

Metal Surface Treatment Topic- Nitriding vs. Carbonitriding Surface Heat Treatment Comparison

Metal Surface Treatment Topic: Environmental Benefits and Advantages of Electroless Nickel

Metal Surface Treatment Topic: The Role of Anodizing in Planetary Gear Reducers